When manufacturers discuss production problems in silicone molding, few issues appear as frequently or silently costly as molding flash. For engineers in high-precision sectors like medical devices, automotive, aerospace, and consumer electronics, the presence of flash—those unwanted burrs or excess silicone at mold parting lines—can mean scrapped parts, rework, production delays, and compliance headaches.

In today’s post, we’ll explore how to approach flash control in silicone molding holistically—from mold design to secondary operations—to ensure your silicone rubber components remain flash-free, dimensionally precise, and ready for high-volume or critical-use applications.

What Is Flash and Why Does It Form in Silicone Molding?

Flash occurs when silicone rubber escapes through gaps in the mold during compression or injection molding, cools and remains visible, or interferes with function, in the final molded silicone product. While it may seem minor, even minimal flash can create tolerance issues, affect sealing in O-rings and gaskets, and violate cosmetic standards, especially in Class 100 cleanroom environments or medical device components.

Flash formation is particularly pronounced in silicone molding due to:

- Material flow properties: Liquid silicone rubber (LSR) has low viscosity and easily flows into micro-gaps.

- Thermal expansion: During vulcanization, materials expand under heat and pressure.

- Inadequate mold alignment: Misaligned parting lines or worn tooling create leakage points.

Whether using standard liquid silicone rubber, platinum-cured silicone, colored silicone, or specialty grades, understanding material behavior is step one in mitigation.

Design Strategies for Flash Prevention

Flash control for silicone rubber starts with robust mold design tailored to silicone’s unique material properties.

Optimizing the Parting Line

The parting line, or the mold separation lines, is often the first and most common area for flash formation. Effective flash control begins with its optimal design to avoid parting line flash.

- Precision machining ensures tight closure with minimal gaps.

- Seal-off geometry and interlocking features create natural flash barriers.

- During product design, positioning the parting line along non-cosmetic or non-functional areas to hide any unavoidable burrs.

- Applying specialized coatings or finishes to reduce material adhesion and improve release.

Poorly defined parting lines are common culprits behind burrs, especially in high-viscosity silicone grades or thin-walled geometries.

Precision Mold Design Considerations

Every component of a mold impacts flash potential. Key elements include:

- Steel quality and finish: Hardened tool steels resist wear at separation lines, while polished surfaces reduce flash adherence

- Venting placement: Micro vents near the end-of-fill areas relieve trapped air, preventing pressure buildup that causes flash

- Cavity tolerance optimization: Proper tolerances between mold halves and inserts prevent overflows and promote part consistency

At Kenvox, DFM reviews ensure that every mold cavity and core is built to exacting standards, reducing the risk of mold mismatch and thermal distortion.

Injection vs. Compression Molding Considerations

Choosing between silicone injection molding and silicone compression molding can also influence flash management:

- Silicone Injection molding: Better suited for high-volume runs and tighter flash control due to precise metering and closed mold injection.

- Silicone compression molding: Preferred for larger, thicker parts and materials with higher durometer; requires more careful mold alignment to prevent flash.

- In both methods, mold cavity pressure control, cure timing, and closing force calibration are vital to prevent flash propagation

Understanding the interplay between the molding process and design choices helps engineers select the right combination for flash-free production.

Equipment and Tooling Advancements

Advanced equipment plays a crucial role in delivering flash-free silicone molding.

Precision Molding Machines and Micro-Molding Systems

High-end silicone injection molding and compression molding machines should offer:

- Shot size accuracy to ensure material dosing is exact, especially for small-to-micro parts.

- Tool alignment systems that maintain parallelism under pressure, minimizing mold separation at the parting line.

- Servo-controlled clamping and injection units that enhance repeatability.

Ejector Pin Design and Seal Engineering

Flash formation often creeps in around improperly designed ejector pin systems in injection molding, especially when dealing with liquid silicone rubber. Kenvox applies:

- Precision-ground ejector pins to reduce tolerance gaps.

- Seal engineering around pin shafts to prevent silicone seepage.

- Mold cavity layouts that minimize edge transitions near ejectors.

These tooling and machine refinements are essential to preventing flash during both prototyping and full-scale production with LSR.

Material & Process Controls in Silicone Injection and Compression Molding

Both silicone injection molding and silicone compression molding require precise coordination between machine settings and material characteristics.

Critical parameters include:

- Injection pressure and fill speed: In injection molding machines, ensure the injection speed and pressure do not cause overpacking and turbulence, which can exacerbate flash.

- Mold temperature: Balanced heating improves flow and prevents early cure at parting lines.

- Silicone viscosity and hardness: High-viscosity or softer grades can reduce flash risk.

- Platinum cure cycles: Timing and temperature must align to avoid incomplete fills or overflow.

- Tolerance planning: Collaborating on dimensional tolerances helps limit overflows.

Flash-free silicone molding depends on dialed-in vulcanization profiles, careful operator training, and real-time quality inspection routines.

Post-Molding: Secondary Operations for Flash Removal

Even with perfect molds for both silicone injection molding or compression molding, micro flash can still appear, especially on small, complex geometries such as implantable medical device parts or LED lighting waterproof barriers.

Kenvox offers multiple flash removal options:

- Manual deflashing: Cutting or breaking off flash using blades or tools

- Tumbling and vibratory tumbling: Used for bulk parts where edge consistency is critical

- Cryogenic deflashing: Using liquid nitrogen and media to break brittle flash without damaging parts

- Robot autogrinders: For large volume, tight tolerance requirements

- Post-curing: Sometimes improves dimensional stability before deflashing

However, secondary operations can increase overhead and time-to-market. The better solution? Eliminate flash upstream.

Flash Control in Action: Kenvox’s Integrated Approach

Kenvox leverages:

- Fully in-house tooling & mold design for liquid silicon rubber, solid silicone rubber, silicone compression, silicone injection molding, and silicone epoxy.

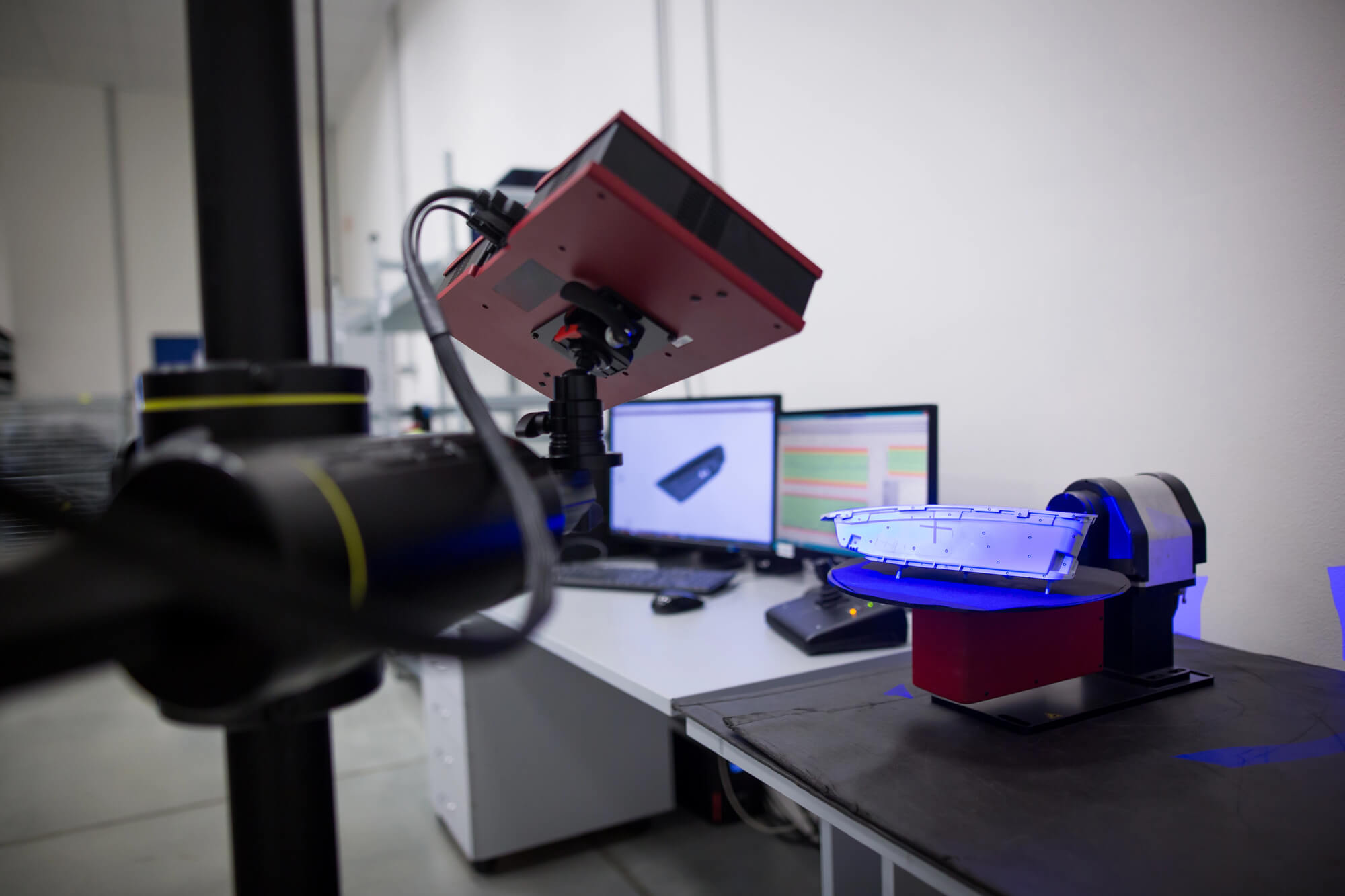

- State-of-the-art equipment for tooling and die creation, including CNC mold machining, EDMs, wire-cutting machines, and more.

- Class 100 cleanroom production for medical-grade components

- In-line ISO 13485, ISO 9001, and ISO 14001 certified quality systems

- A DFM process that includes moldability analysis, gate design, venting simulations, and predictive flash zone detection

- Experience across high & low-volume production for medical, baby, consumer, and automotive markets

From silicone overmolding to rapid prototyping, flash control isn’t just about defect reduction. It’s a competitive advantage.

Prevent Flash Before You Have to Cut It Off

Designing for flash control silicone molding means thinking ahead: from mold parting surfaces to silicone material selection, from pressure dynamics to operator practices. By taking a comprehensive view that integrates mold design, processing conditions, and post-molding strategies, manufacturers can eliminate the most common source of production issues, scrap, and rework.

At Kenvox, we build molds to run flash-free from the start. Contact us today to discuss your project—whether it’s liquid silicone rubber baby products, gaskets, or aerospace silicone components—and discover how we help eliminate flash before it starts.

Explore our silicone molding capabilities or contact us for a free DFM review.