Custom Manufacturing in China and Vietnam

OEM MANUFACTURING

Silicone and Metal Fabrication

DESIGN & DEVELOPMENT

user interface, prototyping and high technology design.

INJECTION PRODUCTION

Low or High Volume Manufacturing, On-Demand Production

SUPPLY CHAIN MANAGEMENT

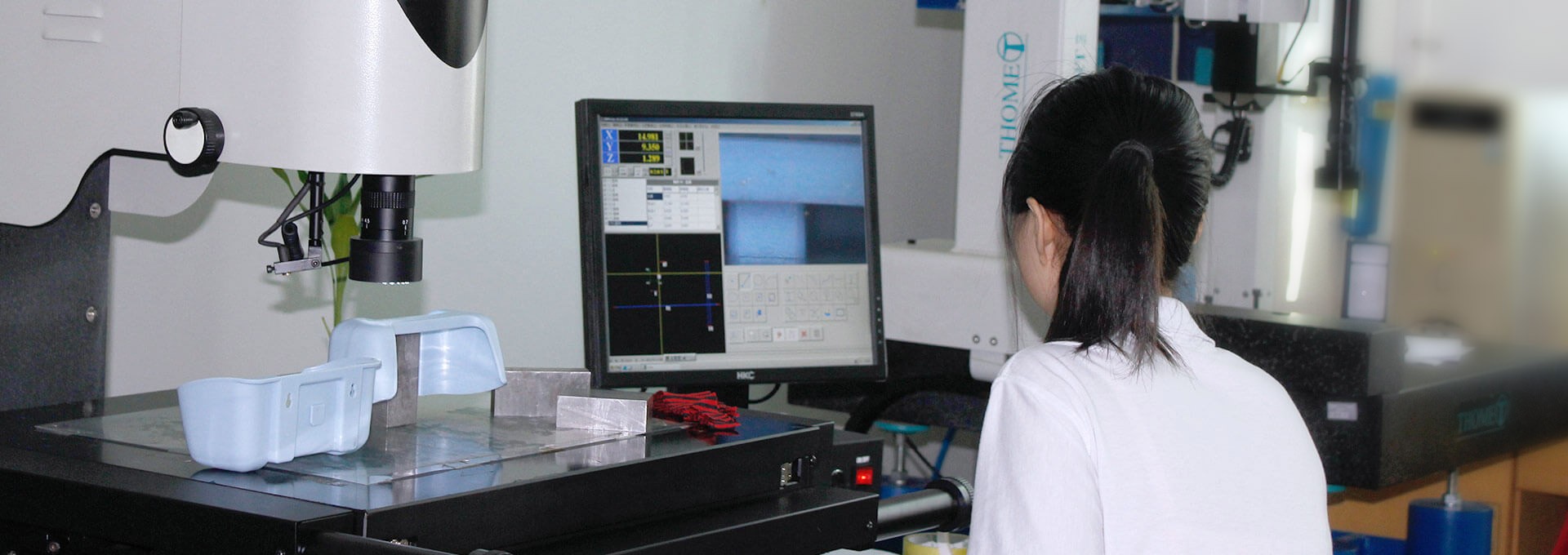

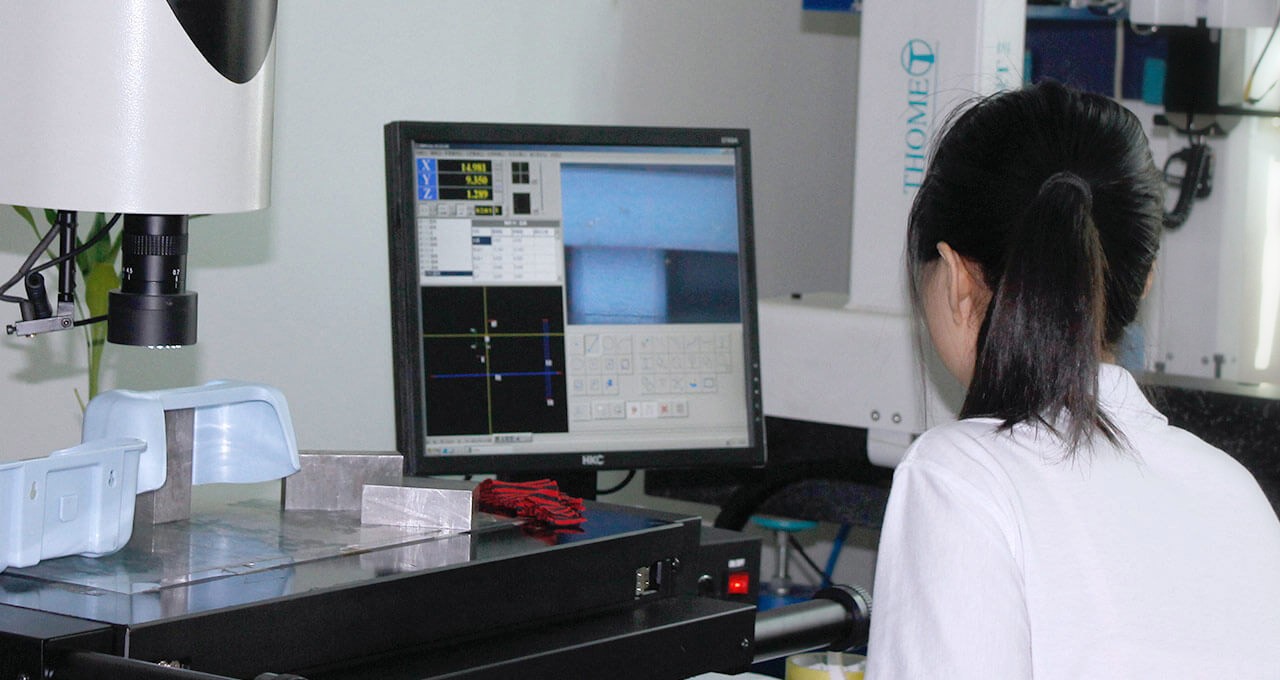

QUALITY CONTROL

ISO13485 and IATF16949.

OEM

MANUFACTURING

DESIGN &

DEVELOPMENT

INJECTION

PRODUCTION

SUPPLY CHAIN MANAGEMENT

QUALITY

CONTROL

years

history

own factories

in China & Vietnam

service bases in

China, Vietnam & USA

manufacturing

partners cooperating

global

clients served

new products developed

and manufactured annually

SERVICES KENVOX PROVIDES

Product Engineering & Development

Our innovative products come from a combination of design, engineering, and manufacturing expertise. Kenvox believes that industry leading products start from meticulous design work.

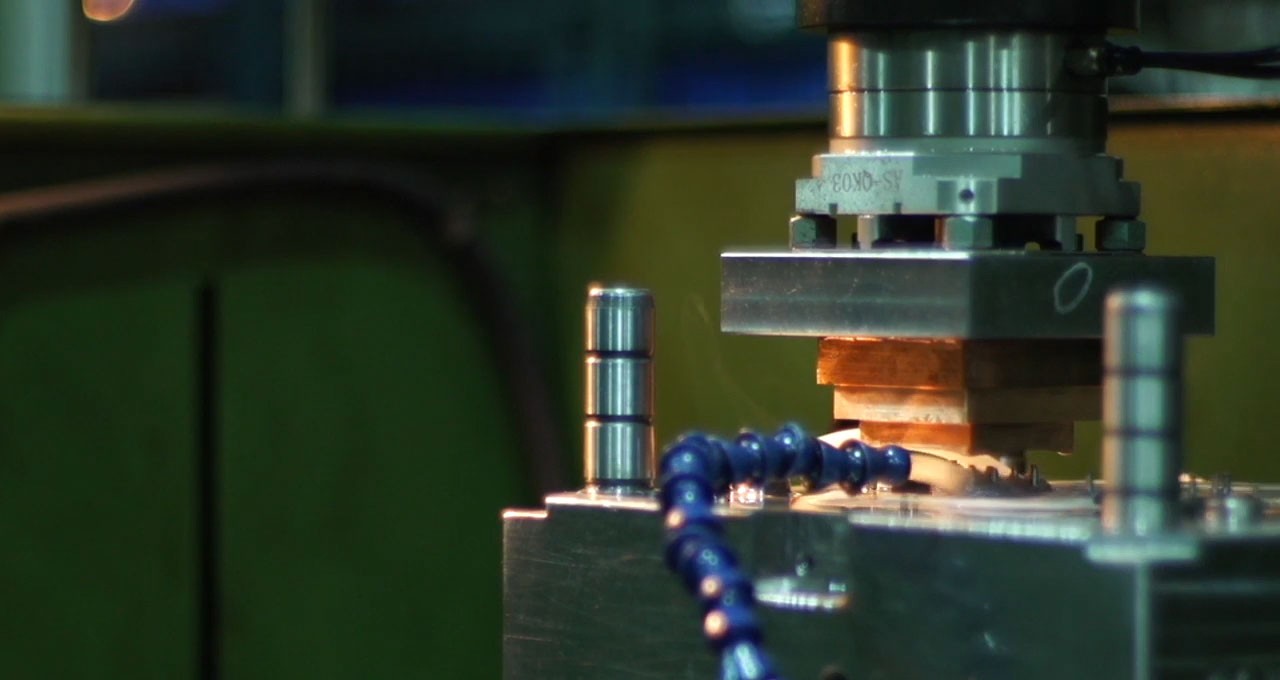

Tooling

Kenvox was originally started as a tool/mold maker in 1989. In the early days, our molds were exported to many overseas customers who were very professional in tooling and mold industry.

Custom Manufacturing

From idea or design concept to finalized ideal product to market, Kenvox’s strong capabilities make us uniquely qualified to be your outsourced contract manufacturing partner, our vertically integrated solutions incorporate a full range of engineer expertise, proven production and ...

Secondary Process

Besides the mold design and making, plastic, silicone and metal producing, Kenvox can also offer some Post Processes in-house to provide one-stop turnkey services to meet customers' variant demands on the surface of finished parts.

Supply Chain Management

As an OEM manufacturing company to blend a wide range of skills and facilities into the right solution for each project, building very close and strategic partnership with many other factories in China in various fields, so as to provide customers with...

Quality Management

Quality is the foundation of our business, Kenvox is dedicated to providing our customers with high quality products. It is our policy to meet or even exceed our customers’ expectations. We maintain the quality management system that meet...