Plastic Injection Molding Services | Kenvox

high-speed cnc,edm

slow wire-cutting

Plastic Injection Molding Services

Manufacturing

Leading professionals in the tool/mold manufacturing industry.

Kenvox maintains strict quality control, deadlines, and voice activities with internal staff.

Plastic Injection

Utilizing 190+ various plastic injection machines, each with a capacity from 30 to 1,000 tons, Kenvox produces over 1,500 tons of plastic materials, servicing mutiple industries like medical, baby products, consumer electronics.

Having over 28 years of industry experience allows Kenvox the ability and confidence to design and/or manufacture any precise or complex projects regardless of size.

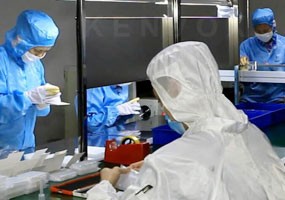

10,000 Class Clean Room Injection workshop- Fully Automatic Running

With the recent increase in medical product demand, Kenvox has established 3 clean rooms used for injection and packaging workshops. These rooms are 100,000-class and 10,000-class per ISO13485.

Over 190 Fully Automatic Injection Machines

Double-shot Plastic Injection Machine

37

China HAITIAN Plastic Injection Machine

63

Taiwan LK Plastic Injection Machine

31

Japan Sumitomo High-Speed Plastic Injection Machine

10

ZHAFIR Plastic Injection Machine

22

China Bester Plastic Injection Machine

16

Plastic Injection Machine above 800 Tons

17

At Kenvox, we’re proud to offer premium custom plastic injection molding services tailored to a wide array of industries. We specialize in crafting precision molded parts for medical devices, automotive applications, and much more. With our focus on both high and low volume production, we leverage efficient and cost-effective processes, ensuring every project is handled with the utmost precision. Our advanced capabilities include insert molding, Liquid Silicone Rubber (LSR) molding, and a suite of secondary operations like CNC machining and laser engraving. With over 28 years of experience, we’re your go-to for high-quality, precision injection molding solutions. Stick with us to uncover how we can elevate your project.

High-Quality Custom Injection Molding for Diverse Industries

We’re proud to offer high-quality custom injection molding that serves a variety of industries, including medical devices and automotive.

Our expertise allows us to handle both high and low volume production with precision and efficiency.

This flexibility guarantees we meet our clients’ diverse needs, making us a trusted partner in their manufacturing process.

recision Injection Molded Parts for Medical Devices, Automotive & More

At Kenvox, we specialize in precision injection molded parts for medical devices, automotive, and various other industries, ensuring high-quality custom molding that meets the exact needs of our clients.

Our precision plastic injection molding services are supported by state-of-the-art tool/mold manufacturing capabilities and a rigorous adherence to strict quality control measures.

With over 190 plastic injection machines and a dedicated 10,000 Class Clean Room Injection Workshop certified by ISO13485, we’re equipped to handle the demanding requirements of clean room injection for medical devices.

Our extensive product offerings cater to a wide range of applications, ensuring that whether it’s automotive components or medical devices, we deliver superior quality molded parts that our customers rely on.

Custom Plastic Injection Molding for High & Low Volume Production

Kenvox consistently delivers high-quality custom plastic injection molding services for both high and low volume production across diverse industries. We’re a go-to among injection molding companies, offering a wide array of plastic manufacturing services.

Our team specializes in high volume plastic injection molding services, ensuring that even the most substantial orders meet our rigorous quality standards. Thanks to our advanced injection mold manufacturing techniques and a fleet of over 190 plastic injection machines, we provide precision injection molding services that cater to specific industrial plastic molding needs.

From production molding to precision components, our expertise in plastic injection molding services makes us a leader in the field. Whether you’re looking for robust production capabilities or detailed custom solutions, we’re here to support your project’s success.

The Injection Molding Process: Efficient & Cost-Effective Solutions

We take raw plastic material and transform it into final parts that meet tight tolerances and uphold consistent quality.

Our injection molding process guarantees that every part we produce reflects our dedication to efficiency and cost-effectiveness.

From Raw Plastic Material to Final Plastic Part

Transforming raw plastic materials into final parts, the injection molding process offers an efficient and cost-effective solution for manufacturing needs.

Our custom plastic injection molding services leverage advanced injection molds and molding technique services to produce high-quality components.

We specialize in manufacturing plastic injection molding services that cater to a wide range of industries, ensuring each project benefits from our extensive experience in plastic molding works.

Tight Tolerances & Consistent Quality in Every Molded Part

Achieving tight tolerances and consistent quality in every molded part, our injection molding process provides efficient and cost-effective solutions for manufacturing needs. We specialize in custom molding, utilizing state-of-the-art techniques in thermoplastic injection and mold design to guarantee precision in plastic parts. Our team’s expertise in prototype molding and plastic injection ensures that from concept to production, each step is optimized for maximum efficiency.

With our advanced manufacturing services, we’re committed to delivering products that meet the strictest standards. Through rigorous control measures, we assure that our injection molding services produce parts with the tight tolerances required for high-quality, reliable outcomes. Whether it’s for medical devices, consumer electronics, or any other industry, we’re here to make your manufacturing process smoother and more reliable.

Advanced Injection Molding Capabilities

We’re stepping up our game with advanced injection molding capabilities, including insert molding and liquid silicone rubber (LSR) molding. Our expertise extends to crafting family molds and multi-cavity production tooling for high-efficiency output.

These techniques allow us to meet the growing demands of industries requiring precision and scalability.

Insert Molding & Liquid Silicone Rubber (LSR) Molding

Expanding our capabilities, Kenvox now offers advanced injection molding services, including insert molding and Liquid Silicone Rubber (LSR) molding, to meet diverse industry needs. Our expertise in plastic injection molding, powered by 190+ plastic injection machines, enables us to undertake a wide array of precision projects.

From plastic manufacturing to tooling for medical products, our services are crafted to deliver high-quality outcomes. Our clean room injection workshop, accredited with ISO13485, guarantees that every product meets the stringent standards required in the medical industry and beyond.

With our extensive experience and state-of-the-art equipment, we’re equipped to handle the complexities of liquid silicone rubber molding and insert molding, providing our clients with innovative solutions tailored to their specific requirements.

Family Molds & Multi-Cavity Production Tooling

Harnessing the power of advanced injection molding, Kenvox introduces family molds and multi-cavity production tooling to enhance precision and productivity in manufacturing. Our state-of-the-art tooling capabilities, combined with our expertise in plastic injection, enable us to tackle the most complex precision projects with ease. By leveraging multi-cavity production, we greatly increase our output without compromising the high standards of quality control that the Kenvox Industrial Group is known for.

Especially in the production of medical products, our 10,000 class clean room injection facilities make certain that even the most stringent hygiene and safety standards are met. This allows us to deliver products that not only meet but exceed the expectations of our clients in critical industries. Trust Kenvox to bring unparalleled efficiency and quality to your next project.

Materials & Design Expertise for Optimal Performance

We appreciate the significance of choosing the appropriate materials and designs for your projects, ensuring they adhere to the highest standards of chemical and heat resistance.

Our guide on injection molding design, including considerations for wall thickness and mold complexity, is customized to enhance your product’s performance.

Let’s explore how our expertise in these areas can greatly enhance your project’s success.

Commonly Molded Plastics with Good Chemical & Heat Resistance

In the domain of plastic injection molding, certain materials stand out for their exceptional chemical and heat resistance, essential for high-performance applications. Our team at Kenvox Industrial Group specializes in plastic injection and plastic molding, using advanced injection molders and thermoplastic molding techniques.

We’re adept at providing molding solutions tailored to meet the rigorous standards of various industries, including the increasing medical product demand. Our plastic fabrication processes, especially in our clean room injection facilities, guarantee products are manufactured under the strictest quality controls.

Leveraging over 28 years of expertise, we’re committed to delivering durable, high-quality components that meet our clients’ specific needs, making us a trusted partner in the plastic molding industry.

Injection Molding Design Guide: Wall Thickness, Mold Complexity & More

Understanding the intricacies of wall thickness and mold complexity is crucial for achieving peak performance in plastic injection molding. Our design guide focuses on these critical aspects, leveraging our extensive plastic design services and plastic engineering expertise. We guarantee ideal wall thickness in our injection molding design to balance strength and material efficiency.

Mold complexity, from simple shapes to intricate parts, is meticulously planned to ensure manufacturability and function.

Our mold making process incorporates advanced molding techniques, supported by our all-inclusive plastic fabrication services. We specialize in thermoplastic injection molding services, crafting designs that meet precise specifications. Through our design guide, we aim to demystify the process, providing clear insights into creating efficient, high-quality plastic components. This approach underscores our dedication to excellence in every project we undertake.

Secondary Operations & Value-Added Services

After molding, we’re not completed with the product; we provide a suite of secondary operations and value-added services to enhance and finish the products.

This includes precise CNC machining, detailed laser engraving and mold texturing, as well as assembly services and the addition of threaded inserts.

These steps guarantee our clients receive fully realized, high-quality finished goods ready for the market.

CNC Machining, Laser Engraving & Mold Texturing

Expanding beyond basic manufacturing, we also specialize in CNC machining, laser engraving, and mold texturing to enhance the functionality and aesthetics of products. These techniques are pivotal in our injection molding and plastic injection processes, ensuring that each piece meets the highest standards of precision and quality.

Our tooling expertise allows us to create detailed, custom designs for a variety of applications, including medical products and other precision projects. Operating within our clean room workshop, we maintain a controlled environment to prevent contamination, essential for the medical industry.

Assembly Services & Threaded Inserts for Finished Products

We also provide meticulous assembly services and incorporate threaded inserts into finished products as part of our secondary operations and value-added services.

At Kenvox Industrial Group, our injection molding services extend beyond just plastic injection. We’re equipped with a state-of-the-art clean room injection workshop, which meets the rising medical product demand with unparalleled precision. Our extensive manufacturing capabilities guarantee that from the initial design to the final assembly, every step is executed with the highest quality standards in mind.

For those looking to enhance their product offerings with durable and reliable components, our assembly services and threaded inserts are the perfect solution.

For more information, don’t hesitate to check out our contact information and let’s discuss how we can elevate your project.

Rapid Prototyping & On-Demand Manufacturing

We recognize the importance of bringing products to market swiftly, which is why we provide custom molded prototypes. Our low-cost aluminum tooling is ideal for short-run production, ensuring you don’t exceed your budget while testing your market.

This approach greatly reduces production time and costs, making your journey from concept to market smoother and faster.

Custom Molded Prototypes for Faster Time-to-Market

In today’s fast-paced market, our custom molded prototypes offer a streamlined path to faster time-to-market through rapid prototyping and on-demand manufacturing services. With our advanced injection molding services, we handle everything from plastic injection to complex tool/mold manufacturing.

Our commitment to strict quality control guarantees that even the most precise projects meet the highest standards. Given the recent spike in medical product demand, our 10,000 Class Clean Room capabilities allow us to meet stringent requirements, making certain that our prototypes are suitable for a wide range of applications.

Our extensive industry experience, combined with a large plastic materials capacity, enables us to deliver custom molded prototypes quickly, aiding clients in addressing market demands more efficiently.

Low-Cost Aluminum Tooling for Short-Run Production

Why settle for long lead times when our low-cost aluminum tooling offers a swift solution for short-run production and rapid prototyping? At Kenvox, we’re not just another molding company; we’re your partners in bringing your plastic product molding ideas to life.

Our plastic injection services are designed to meet the dynamic needs of industries requiring high-quality plastic injection molding solutions. With our expertise, we guarantee that each project, regardless of its complexity, benefits from our extensive experience as plastic injection manufacturers.

We provide a range of plastic molding variations, enabling us to cater to unique requirements. Our approach to plastic services combines efficiency with affordability, ensuring that short-run production doesn’t compromise on quality. Trust us to deliver exceptional results, on time and within budget.

High-Volume Production Molding with Tight Quality Control

We’re entering the domain of high-volume production molding, focusing on how we sustain cost efficiency and optimize the supply chain.

Our use of sturdy aluminum and machined molds guarantees we meet the demands of large-scale production without sacrificing quality. This approach allows us to uphold strict quality control throughout every step, guaranteeing every product meets our high standards.

Mass Production with Cost Efficiency & Supply Chain Optimization

Harnessing over 28 years of expertise, our team specializes in mass production with cost efficiency and supply chain optimization, ensuring high-volume production molding meets stringent quality standards.

We’re at the forefront of injection molding, offering unparalleled plastic injection manufacturing and tooling services. Our production services are designed to generate a vast array of plastic parts, from components for consumer electronics to critical medical products, all within our state-of-the-art clean room facilities.

This commitment to quality control and supply chain optimization means we’re not just meeting deadlines; we’re also ensuring each product adheres to the highest standards of quality. Our approach combines the best of technology and human talent, making us leaders in the field.

Durable Aluminum & Machined Molds for Large-Scale Production

At the core of our high-volume production molding capabilities, durable aluminum and machined molds guarantee tight quality control and reliability.

We specialize in injection molding, utilizing over 28 years of industry experience to produce high-quality plastic materials for various applications, including medical products.

Our mold manufacturing process is fine-tuned for precision projects, ensuring every tooling aspect meets the strictest standards.

With our clean room injection facilities, we’re equipped to handle even the most sensitive production requirements, maintaining an environment that safeguards the integrity of each piece.

Our commitment to excellence in plastic injection and our ability to navigate complex tooling challenges underscore the quality control that’s pivotal in delivering products that consistently exceed expectations.

Why Choose Kenvox for Your Injection Molding Project?

We acknowledge that selecting the appropriate partner for your injection molding project is vital.

At Kenvox, we provide high-precision, high-quality molded parts along with cost-effective solutions, from prototyping to full production.

Our extensive experience and advanced facilities guarantee the success of your project.

High-Precision, High-Quality Molded Parts

Choosing Kenvox for your injection molding project guarantees high-precision, high-quality molded parts, thanks to our 28 years of industry experience and advanced manufacturing capabilities. We specialize in plastic injection and tool/mold manufacturing, ensuring that every component meets the highest standards of quality. Our 10,000 Class Clean Room is specifically designed for the production of medical products, emphasizing the importance of clean room injection in maintaining product purity and compliance with industry regulations.

Our strict quality control processes are integral to our operations, ensuring that every project, big or small, adheres to the most stringent quality standards. With Kenvox Industrial Group, you’re not just choosing a service provider; you’re partnering with a leader in injection molding that’s committed to delivering high-precision, high-quality parts every time.

Cost-Effective Solutions from Prototyping to Full Production

Kenvox offers cost-effective solutions from prototyping to full production, ensuring your project benefits from our decades of expertise and advanced technological capabilities. With over 190 plastic injection machines ranging from 30 to 1,000 tons, we’re equipped to tackle projects of any scale.

Our all-encompassing plastic services include everything from tooling and plastic molding to final plastic production, ensuring smooth shifts at every stage. For medical products, our state-of-the-art clean room facilities meet the highest industry standards, ensuring contamination-free manufacturing.

Frequently Asked Questions

How Does Kenvox Handle Intellectual Property and Confidentiality Agreements for Custom Plastic Injection Molding Projects?

We take intellectual property and confidentiality very seriously for our custom plastic injection molding projects, ensuring all agreements are strictly adhered to protect our clients’ ideas and innovations throughout the manufacturing process.

What Specific Steps Does Kenvox Take to Ensure Environmental Sustainability in Its Plastic Injection Molding Processes?

We prioritize environmental sustainability by adopting green manufacturing practices, recycling waste materials, and using energy-efficient machinery. Our commitment includes monitoring emissions and investing in technologies that reduce our environmental footprint throughout the injection molding process.

Can Kenvox Provide Detailed Case Studies or Examples of Challenging Plastic Injection Molding Projects They Have Successfully Completed in the Past?

We can indeed share detailed case studies or examples of challenging projects we’ve successfully tackled. Our extensive experience allows us to handle complex demands, showcasing our expertise across various industries.

How Does Kenvox Integrate With Client’s Existing Supply Chain and Logistics Operations for Seamless Production and Delivery of Injection Molded Parts?

We integrate with clients’ supply chains and logistics by closely coordinating with their teams, ensuring seamless production and delivery of injection molded parts. This collaboration optimizes timelines and maintains the quality our partners expect from us.

What Are Kenvox’s Policies and Procedures for Handling Unexpected Production Challenges or Delays During the Plastic Injection Molding Process?

We tackle unforeseen production challenges by swiftly adapting our processes, communicating openly with our clients, and implementing contingency plans to minimize delays. Our team’s proficiency guarantees we uphold quality and meet deadlines efficiently.