Engineering the Future of Manufacturing.

Engineering Dreams,Building Reality.

Engineering the Future of Manufacturing.

Engineering Dreams,Building Reality.

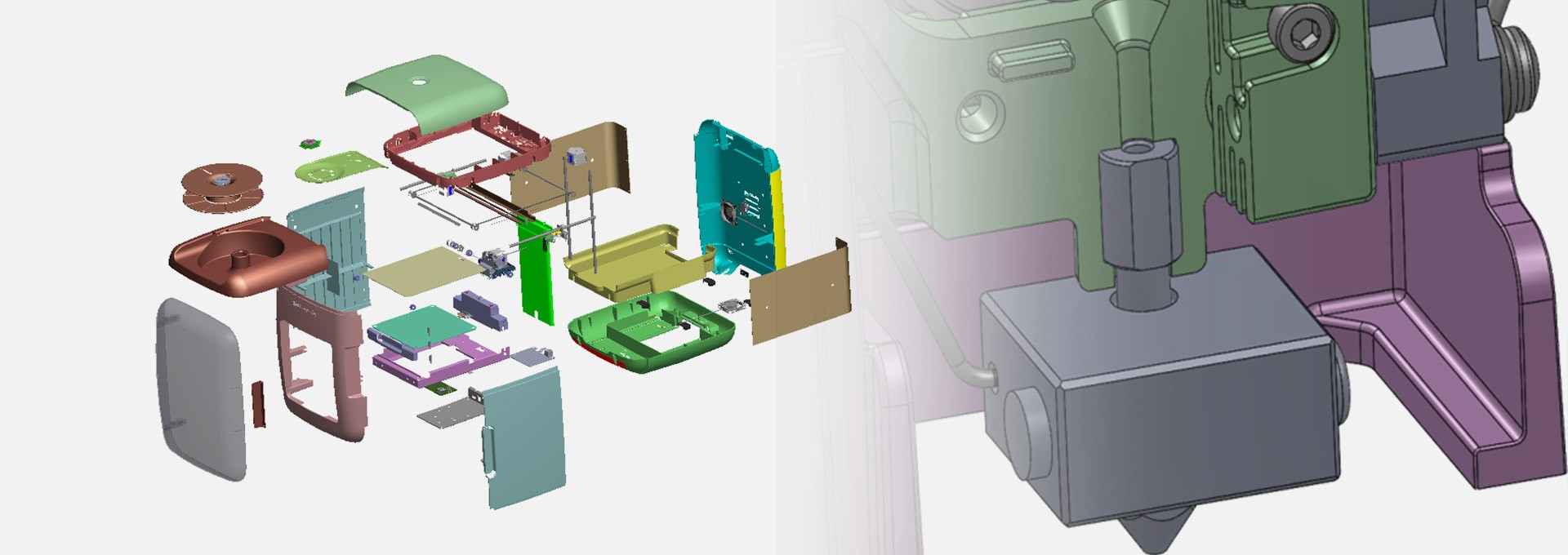

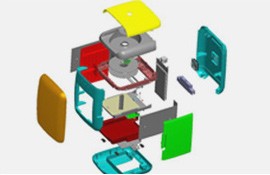

Product Design & Development

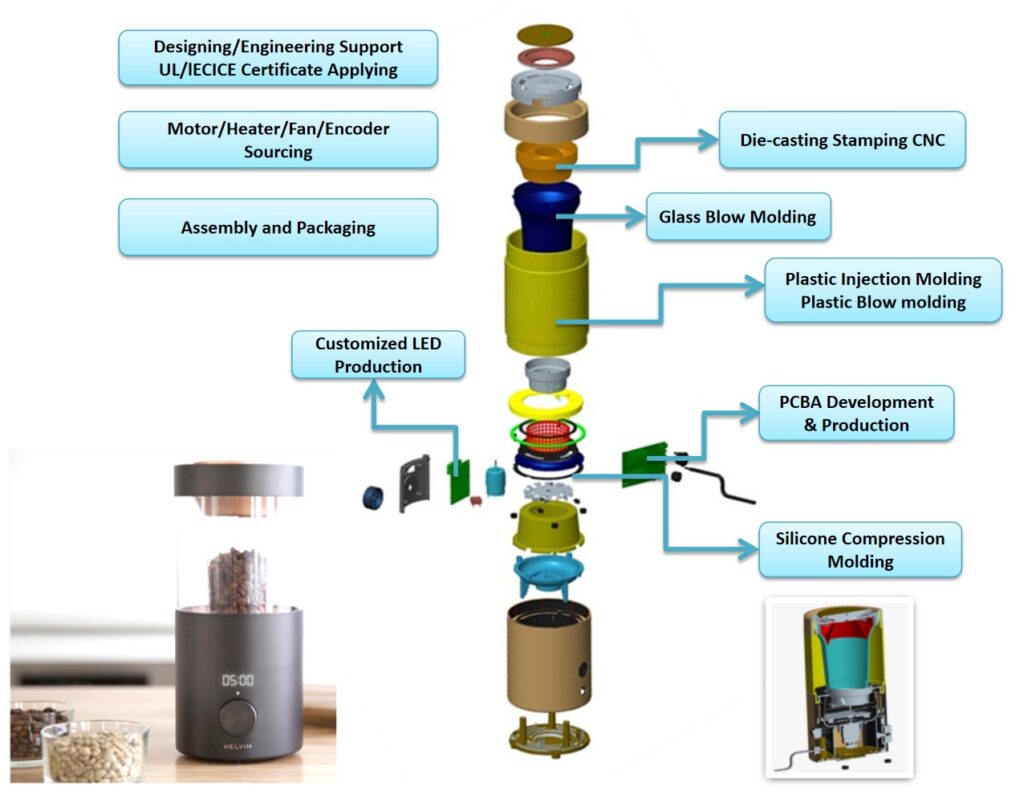

At Kenvox, we’ve been leading the contract manufacturing industry for over 34 years. Our team of highly skilled engineers has more than 15 years of experience in product engineering, development, and manufacturing. With expertise in plastic, silicone, and metal, we’ve worked on over 300 complicated NPD projects.

At Kenvox, we’ve been leading the contract manufacturing industry for over 34 years. Our team of highly skilled engineers has more than 15 years of experience in product engineering, development, and manufacturing. With expertise in plastic, silicone, and metal, we’ve worked on over 300 complicated NPD projects.

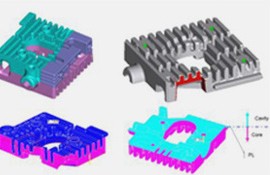

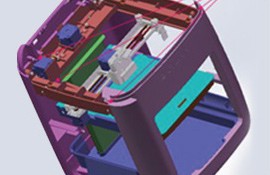

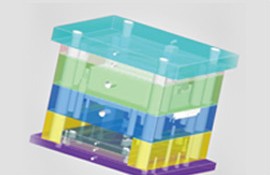

We offer comprehensive solution for innovative concept exploration, rapid prototyping, injection molding, DMF, DFMA and mold design& mold flow analysis provides you with the best tools and expertise to bring your product vision to life.

We understand that you need a partner who can help you navigate the complex process of developing and producing your product. That’s why our R&D team stays up-to-date with industry trends, continuously improving existing products and processes, and developing new ones. Our team is dedicated to providing you with innovative solutions that meet your unique requirements.

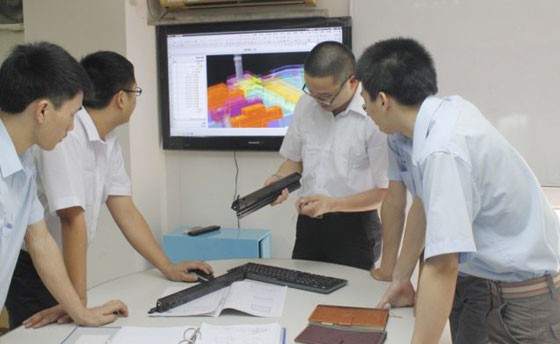

We believe that teamwork is essential for the success of any project. That’s why we set up specific project teams to develop and monitor the entire process, with dedicated project managers acting as customer representatives and independent “third eyes” to oversee every aspect of development and production.

We’re dedicated to your success. With our top-tier engineering and expertise, we’ll deliver innovative solutions that keep you ahead of the competition. Let us partner with you to exceed your expectations and achieve your goals.

Your unique design needs our expert Engineering

Support and Design for Manufacturabilty (DFM)

Kenvox has extensive design for manufacturing experience we bring to bear on new product introduction projects, and new OEM products introduction projects working with customers to improve all aspects of the design, from reliability to repeatability to cost-effectiveness.

Reducing product cost through design is something that takes an immense knowledge of the factors and processes behind the product; with a wide range of in-house production capabilities, Kenvox knows what drives cost reductions on both a component and assembly level. We share that knowledge with the customer, helping them to improve cost at the most critical stage: design.

A key concern at Kenvox is how to improve product reliability, reduce potential for failure, and lower the return risk to our customers. We work in close cooperation with customers on troubleshooting problematic components or assemblies and provide input from both our team and upstream suppliers in order to de-risk customer designs.

Working with the customer to help ensure that the customer’s design is updated to best suit production in China, by suggesting locally available parts and vendors, alternative materials, or other adjustments to ensure the best lead time, and a competitive price.

We specialize in engineering and development for custom plastic, silicone, and metal components, delivering industry-leading product engineering solutions that guide your ideas from initial concept through final production. Our experienced product engineers and mechanical engineers have created countless successful products, demonstrating deep expertise in product design and engineering, design and development, and innovation engineering and development across multiple sectors.

At Kenvox, our product engineering services cover the full spectrum of the product engineering process. That includes design optimization, product lifecycle engineering and development, cost-effective manufacturing strategies, and reliability improvements—all supported by structured project management, detailed market research, and product strategy alignment with your goals.

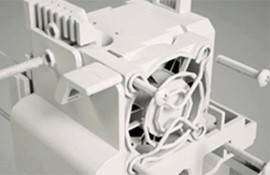

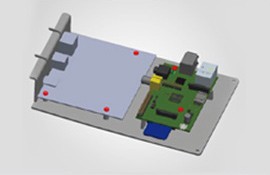

We excel in plastic injection molding, liquid silicone rubber (LSR) molding, and precision-machined metal components through CNC machining and forming. Whether you’re developing new technologies, refining existing products, or exploring product innovation, our team ensures seamless integration of engineering and manufacturing through a systematic process that transforms product ideas into high-performing, market-ready solutions.

Our engineering team also offers extensive R&D product engineering, product management, product research and development, and product engineering management, ensuring every step—from CAD design to prototyping—follows best practices in product development and engineering solutions. We proudly serve a broad range of industries and tailor our engineering applications for product development to the unique challenges of each sector.

Product engineering is the foundation of creating innovative, functional, and commercially successful products. As a leading product development consultancy and engineering consultancy, we offer a comprehensive suite of engineering and product development services that span mechanical engineering, industrial design, software engineering, and systems engineering. Our approach blends creativity, engineering principles, and strategic thinking to develop products that meet real market demands.

Kenvox’s product engineering and development team collaborates closely with clients to understand customer requirements, target audience insights, consumer preferences, and overall product strategy. This ensures each engineering product design aligns seamlessly with business goals and product roadmaps.

By leveraging our product engineering solutions, businesses can accelerate the product development process, reduce manufacturing costs, simplify the product development lifecycle, and achieve faster go-to-market success. Whether you’re developing a new mechanical system, electronic product, silicone component, or fully connected device, our engineers design and build solutions that enhance product performance, reliability, and marketability.

We focus on engineering variations, continuous improvement, high-quality materials, and user-centered design—allowing companies to innovate faster, develop products more efficiently, and maintain a competitive advantage. Our structured development process ensures a smooth transition from concept to prototype to final product.

We provide complete design and engineering solutions for plastic, silicone, and metal products, ensuring exceptional functionality, manufacturability, cost efficiency, and durability. Our product engineering process is structured around the entire product lifecycle, guiding every stage from early design concepts to prototype development, testing, and full-scale mass production.

Our development team and engineering management experts integrate design concept prototypes, material selection, functional testing, supply chain planning, and production optimization to help clients develop products with long-term reliability, aesthetic appeal, and strong market positioning.

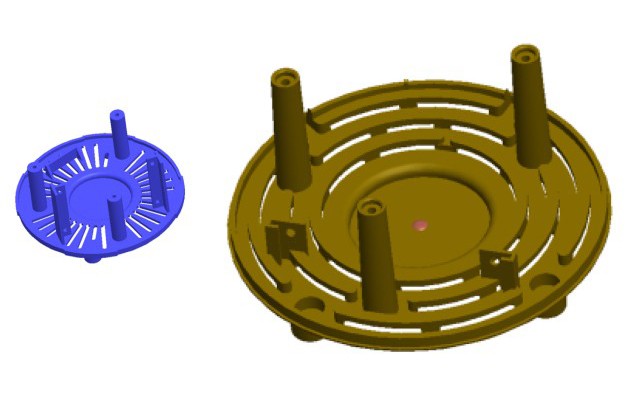

We deliver specialized product engineering and development across plastic parts, silicone components, and precision metal assemblies. This includes detailed CAD modeling, prototype materials selection, mold design, engineering analysis, and the development of custom production processes.

Plastic product engineering using advanced injection molding

Silicone engineering through LSR molding and HCR molding

Metal engineering through CNC machining and forming

Product engineering variations to meet unique application demands

Engineering product development aligned with industry standards

Our engineering solutions for development allow us to build products that meet strict usability, performance, and manufacturing criteria. By collaborating closely with clients through continuous user feedback and client feedback, we adjust engineering product design to meet exact requirements.

Our plastic engineering team specializes in product engineering solutions using plastic injection molding, offering high-precision manufacturing supported by detailed mold design, mold flow analysis, and computer-aided design. We optimize for:

Structural integrity

Aesthetic appeal

Material compatibility

Processing efficiency

Cost-effective manufacturing

Our engineers design plastic products that perform consistently, leveraging engineering principles, new technologies, and continuous monitoring throughout the development of products.

Our expertise in liquid silicone rubber molding supports critical medical, industrial, and consumer applications requiring reliability, biocompatibility, and high performance. We deliver:

Full lifecycle design and development

DFM (Design for Manufacturing) integration

Mold design for silicone and LSR

Cost reduction strategies

Performance and material testing

With LSR’s superior mechanical properties and resistance to extreme temperatures, the product engineering process ensures medical-grade consistency and high-volume manufacturing scalability. We align design decisions with product engineering strategy for optimal functional performance.

Our metal engineering team develops high-precision components using advanced CNC machining, metal forming, laser cutting, and finishing processes. These solutions support industries where tight tolerances, mechanical strength, and long-term reliability are essential.

We focus on:

Optimized design concepts

Performance durability

Engineering applications for product development

Metal product engineering variations

Design localization for cost reduction

This ensures all engineering products meet client expectations while remaining cost-competitive.

Our product lifecycle management approach manages the entire journey from concept to production to long-term market support. This includes engineering project development, documentation control, risk analysis, manufacturing plans, and quality assurance procedures.

We integrate:

Digital thread connections

Engineering and product design alignment

Software, hardware, and mechanical system synergy

Product engineering management

Continuous improvement and data collection

Regulatory requirements and industry standards

This approach enables faster scaling, reduced costs, and optimized product lifecycle performance.

Shifting from design concept to functional prototype requires rigorous engineering analysis, development product strategy, and integrated engineering and product development workflows. We support:

Engineering of products with strong functional design

System architecture planning

Product development engineering aligned with goals

Material sourcing and supply chain planning

Prototype development and testing cycles

By integrating mechanical engineering, materials science, and market analysis, we ensure the final product meets both user needs and technical performance standards.

At this stage of the development of product engineering, we refine design concepts using advanced prototyping tools and computer-aided design to validate functionality, manufacturability, and user experience.

We conduct:

Functional prototyping

Structural analysis

Material testing

Product performance evaluation

End-user surveys for user feedback

Failure analysis and continuous improvement cycles

Testing ensures every engineering product is market-ready, safe, and built for long-term performance.

Scaling from prototypes to mass production requires tactical engineering and product development process optimization. We handle:

Manufacturing cost reduction

Product reliability improvement

Localized production strategies

Supply chain resilience planning

Production line setup and optimization

Our engineering product development model guarantees a smooth transition between development stages.

Our advanced engineering capabilities allow us to transform even the most complex product design and development challenges into functional, manufacturable, and market-ready solutions. We integrate engineering and design, engineering management, and cross-functional development engineering to support both startups and global brands with scalable engineering solutions.

Our goal is to enhance performance, reduce costs, elevate the user experience, and create engineering products that meet the highest industry standards—while maintaining seamless integration across mechanical, electrical, software, and materials engineering disciplines.

We specialize in converting design concepts into functional, manufacturable products using advanced design and engineering principles. Our holistic approach blends industrial design, mechanical engineering, materials science, and engineering for product development, ensuring that each final product is both visually compelling and structurally robust.

Our design team combines creativity, strategic thinking, and analytical engineering principles to develop products that perform exceptionally well in the real world. We focus on:

Ergonomics and user-centered design

Mechanical systems engineering

Aesthetic appeal integrated with structural integrity

High-quality materials and prototype materials selection

Predictive analytics for performance forecasting

Market analysis and consumer preference insights

We apply engineering applications for product development to guarantee that each design concept is feasible, cost-effective, and optimized for full-scale production.

Material selection plays a crucial role in the durability, safety, and performance of any engineered product. Our engineers evaluate:

Durability under mechanical stress

Chemical resistance for industrial and medical applications

Environmental resistance for outdoor products

Compatibility with silicone, metal, and plastic components

Long-term stability, color retention, and fatigue resistance

This data-driven approach ensures that each product meets performance goals while optimizing cost and longevity.

Our engineers implement DFM early in the product engineering process, reducing production complexities and improving reliability.

We optimize:

Mold design and tooling

Tolerances and draft angles

Raw materials and additional raw materials

Assembly steps

Product reliability and failure minimization

The result is a highly manufacturable product with fewer revisions, reduced lead times, and improved cost efficiency throughout the product development lifecycle.

We accelerate development schedules through rapid prototyping, allowing our clients to test design variations and engineering concepts quickly and cost-effectively. Our NPI process bridges the gap between prototype development and mass production, ensuring that every engineering product development step is validated and market-ready.

Our fast-track programs support:

Injection-molded plastic parts

Liquid silicone components

CNC-machined metal assemblies

Multi-material product systems

We leverage:

Engineering CAD software

Digital thread integration

Automated production workflows

Quick-turn tooling

Product design localization

This rapid process shortens the timeline from idea to final product while reducing risks.

Our testing and validation processes ensure compliance with regulatory requirements and international industry standards. This phase includes:

Mechanical stress testing

Environmental conditioning

Human factors testing

Product performance evaluations

Safety validation

Functional testing of electronic and mechanical assemblies

We gather user feedback, perform end-user surveys, and incorporate consumer insights to refine usability and product-market fit.

Sustainability is a core part of our engineering solutions. As companies increasingly seek eco-conscious products, our team integrates carbon reduction strategies, recyclable materials, and long-life engineering principles into the development process.

We focus on:

Reducing carbon emissions during production

Designing recyclable components

Sustainable materials selection

Minimizing waste through optimized tooling

Energy-efficient manufacturing processes

This ensures compliance with global sustainability standards and corporate social responsibility goals.

Global supply chains influence cost, lead times, and product quality. Our engineering development processes incorporate:

Manufacturing optimization

Competitive pricing through regional production

Predictive supply chain analytics

Reduced reliance on single suppliers

Risk mitigation strategies

End-to-end transparency

Our approach ensures timely delivery—even during global supply chain disruptions.

Our strength lies in our diverse and highly skilled development team, composed of:

Experienced product engineers

Mechanical engineers

Software engineers

Product development engineers

Designers and CAD specialists

Product managers

Project management professionals

Quality engineers

R&D specialists

With 500+ English-proficient team members, we blend engineering rigor with creative thinking, strategic planning, and continuous monitoring throughout the product development lifecycle.

Our engineering and product design philosophy emphasizes:

Seamless integration

Continuous improvement

User-friendly features

Market demands alignment

Regulatory requirements compliance

Cross-functional collaboration between engineering, design, and the finance team

This allows us to consistently develop products that exceed expectations.

We rely on a modern blend of digital tools, engineering platforms, and cloud-based systems to streamline the entire development process. Our toolset includes:

Google Cloud Platform

Amazon Web Services

Microsoft Azure

Jira project management

GitHub version control

Jenkins CI/CD

FEA and CAD engineering software

Simulation systems for stress, flow, and thermal analysis

These tools ensure:

Efficient collaboration

Reliable data collection

Accurate simulations

Faster iteration cycles

Real-time client communication

High-quality engineering outcomes

Our advanced technology stack enhances precision and enables seamless integration from concept to prototype to full production.

Connected devices require seamless communication between hardware, firmware, cloud platforms, and mobile apps. We develop digital and connected products using:

IoT systems

Artificial intelligence

Machine learning

Predictive analytics

Embedded systems engineering

Software engineering integration

We support businesses in developing products with smart features, enhanced user experiences, and cutting-edge functionality. Our engineering for products extends into wearable devices, consumer electronics, industrial IoT systems, and medical-grade digital solutions.

Sustainability remains central as we engineer devices that reduce energy consumption and align with evolving regulations.

Kenvox offers a competitive advantage through our unmatched expertise in plastic, silicone, and metal product engineering. We align engineering, design, and business aspects to deliver successful, profitable products.

Choosing Kenvox means choosing:

Advanced design optimization

World-class engineering solutions

Manufacturing cost reduction

Custom engineering product development

Product reliability improvements

Optimal design for manufacturability

Exceptional product innovation

Detailed product roadmaps for market success

Our team ensures your ideas transition into functional, high-quality products that deliver real value.

We support your company by providing:

Faster development cycles

Lower production costs

Improved performance and product quality

Stronger market positioning

Expert regulatory support

Seamless go-to-market strategies

Engineering solutions tailored to your business

We are not just a manufacturer—we are your long-term product engineering and development consultancy partner.

How does Kenvox handle intellectual property rights and confidentiality?

We employ strict confidentiality protocols, NDAs, secure file handling, and isolated development environments to protect every client’s IP throughout the entire engineering of products.

Can Kenvox help with regulatory certifications for global markets?

Yes. We assist with compliance for FDA, CE, RoHS, REACH, ISO, UL, and other international regulatory requirements.

Does Kenvox offer post-manufacturing support?

Absolutely. We provide maintenance, repair services, upgrades, spare parts, and end-of-life recycling programs.

Does Kenvox integrate customer feedback into future development?

Yes. We incorporate customer feedback, user testing, and market analysis into every engineering product design cycle.

How does Kenvox ensure timely delivery despite supply chain issues?

We mitigate risks through diversified suppliers, regional manufacturing, safety stock strategies, and real-time supply chain monitoring.