high-speed cnc,edm

slow wire-cutting

high-speed cnc,edm

slow wire-cutting

years

history

own factories

in China & Vietnam

service bases in

China, Vietnam & USA

manufacturing

partners cooperating

global

clients served

new products developed

and manufactured annually

ISO9001, ISO14001, ISO13485 , IATF16949 and BSCI, systems are strictly followed in Kenvox daily work in every procedure.

Leading professionals in the tool/mold manufacturing industry.

Kenvox maintains strict quality control, deadlines, and voice activities with internal staff.

Kenvox originated in 1989 as an exclusive tool maker, exporting most of their tooling to overseas factories encompassing all ranges of industry. Our mold manufacturing versatility is reinforced by an expert staff of tool and die professionals, having access to sate-of-the-art equipment.

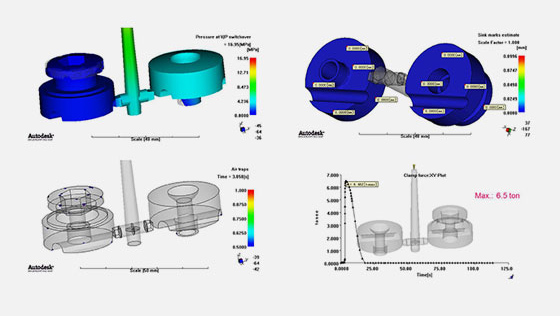

By taking a scientific and strategic approach for mold design, we make intelligent decisions based on the part geometry, characteristics of the molding material, the specific molding process, and the estimated product life cycle. Our mold design process involves the use of various analysis and testing tools to validate our design concepts and ensure a high rate of conforming product. We manufacture precision quality molds with features such as exchangeable cores, hot runner systems, and multi-cavity configurations for molds.

Skilled and experienced designers are dedicated to meeting quality standards in the following industries: automotive, medical, electronic, baby-care, kitchenware, and many others.

3-axis Stroke: 350*250*250mm Positional Accuracy: ±0.003mm Repeatability Accuracy: 0.001mm

3-axis Stroke: 400*300*250mm Positional Accuracy: ±0.003mm Repeatability Accuracy: 0.001mm

3-axis Stroke: 350*250*300mm Positional Accuracy: ±0.003mm Repeatability Accuracy: 0.001mm

3-axis Stroke:400*250*220mm Positional Accuracy:±0.3mm Repeatability Accuracy:±0.15mm

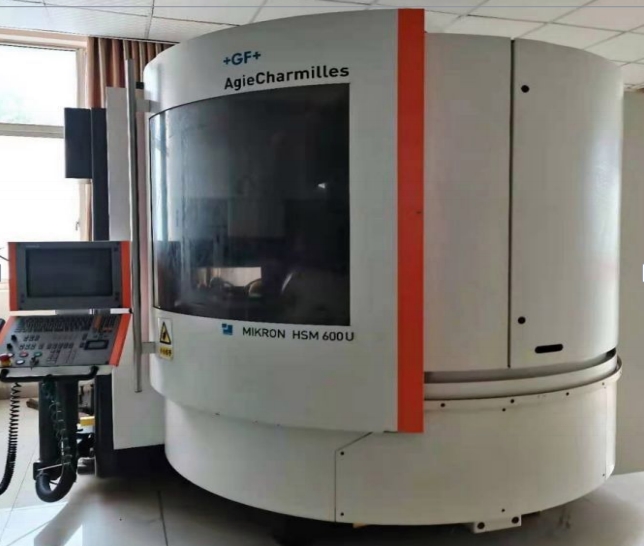

3-axis Stroke: 600*600*500mm Positional Accuracy: ±0.002mm Speed: 42000 (rpm)

3-axis Stroke: 500*450*350mm Positional Accuracy: ±0.002mm Speed: 42000 (rpm)

3-axis Stroke: 650*550*450mm Positional Accuracy: ±0.005mm Speed: 24000 (rpm)

3-axis Stroke: 860*550*550mm Positional Accuracy: ±0.005mm Speed: 15000 (rpm)

| Name | Quantity | Country of origin |

|---|---|---|

| MAKINO Mirror EDM | 4 | Japan |

| AgieCharmilles Mirror EDM | 8 | Switzerland |

| AgieCharmilles Slow Wire-cutting Machine | 4 | Switzerland |

| Mikron High-speed CNC | 3 | Switzerland |

| FANUC CNC | 5 | Japan |

| DAHLIH CNC | 4 | Taiwan |

| Wire-cutting Machine | 8 | China |

| Drilling Machine | 1 | China |

| Milling Machine | 10 | Taiwan |

| Grinding Machine | 11 | Taiwan |

| EDM | 4 | China |