In the race to build better products faster, rapid prototyping has emerged as a game-changer for engineers, designers, and manufacturers. Whether you’re building initial prototypes to explore a concept or refining functional prototypes ahead of full-scale production, the ability to quickly model, test, and iterate using advanced prototyping tools and AI-powered prototyping technologies is a competitive necessity and not just a luxury.

From interactive components in consumer electronics to biodegradable materials in sustainable packaging, today’s prototyping ecosystem supports everything from the earliest prototypes to geometric prototypes that simulate full-scale behavior. Combined with the power of computer-aided design (CAD), digital 3D models, and design for manufacturing (DFM) best practices, modern prototyping is accelerating the entire product development process while also cutting costs, reducing delays in production, and boosting agility in product development.

In this comprehensive guide, we’ll explore what a rapid prototype is, the process, its benefits, stages, industry applications, and how Kenvox brings speed, precision, and cost-efficiency to your product design and production ramps.

What Is Rapid Prototyping?

At its core, rapid prototyping is a suite of manufacturing techniques used to quickly fabricate a physical prototype or digital model of a product or component. These techniques are designed to accelerate the design cycle, allowing teams to visualize, test, and refine their ideas far earlier in the product development timeline.

Unlike traditional methods that require full tooling or molds before a single unit can be tested, rapid prototyping leverages advancements like 3D printing technologies, CNC machining, and AI-powered prototyping tools to quickly produce models based on the initial designs created in prototyping software like CAD. This approach significantly reduces manufacturing costs, speeds up testing, and minimizes the risks of costly issues before production.

It’s especially critical when working with complex designs or interactive components—such as those found in consumer electronics, medical devices, or automotive systems—where rigorous testing, usability testing, and field testing are essential for market success.

From Idea to Model: Why It Matters

By producing high-fidelity prototypes early in the development cycle, teams can:

- Validate assumptions about material properties and component behavior.

- Detect flaws in product design before entering the production phase.

- Iterate quickly with feedback from testing and market testing.

- Present realistic physical models to stakeholders, investors, or even customers.

- Obtain accurate prototyping that supports future mass production.

Moreover, AI-powered solutions integrated into modern design systems now allow GPT models and advanced simulations to further streamline component-level development. This enables designers to preemptively address production issues and simulate user experience before even building a prototype layer.

Key Benefits of Rapid Prototyping

Rapid prototyping offers a multitude of advantages that enhance the product development process. From getting crucial early user feedback to reducing costs and risk, these benefits empower teams to push the boundaries of creativity and innovation.

Speeds Up Product Development

Rapid prototyping dramatically accelerates the product development process by allowing teams to quickly transform digital 3D models into physical prototypes and even a Minimum Viable Product. Instead of waiting weeks for traditional molds or tooling, engineers can go from CAD model to high-fidelity prototypes in a matter of days using the latest design tools and additive manufacturing technologies.

This speed provides a crucial advantage in compressed development cycles, particularly when agility in product development is critical. Whether you’re validating a geometric prototype or testing user interaction with UI components, rapid prototyping minimizes bottlenecks and reduces delays in production.

Enables Early Design Validation

Creating initial prototypes early in the design cycle lets teams evaluate form, fit, and function while still making changes without significant cost. This is especially beneficial when working with complex designs or engineering product development projects that require close attention to tolerances, interlocking parts, and functional testing.

Field testing and usability testing can also be conducted with early physical models, allowing product teams to gather feedback for design improvements before full-scale production. Any problems identified can be addressed immediately while still in the design phase, saving time and avoiding expensive redesigns later in the production phase.

Improves Communication and Collaboration

Prototypes are communication tools. Physical models and digital designs help align cross-functional teams, including engineering, design, software development, and marketing, by providing a shared reference. Whether you’re reviewing React components or CAD models, everyone can visualize the intended outcome.

Moreover, functional prototyping serves to create valuable assets when securing approvals or presenting to stakeholders, where static renderings or documents might fall short.

Supports Functional Testing

Functional prototypes allow for rigorous testing of mechanical properties, tolerances, ergonomics, and user experience. Depending on the technique, you can create later-stage prototypes capable of real-world use, including durability testing, load-bearing analysis, or environmental stress checks.

Prototyping with 3D printing enables quick iterations, while CNC-machined components offer a closer simulation to the final production parts. In all cases, feedback from testing plays a pivotal role in refining the product before entering mass production.

Cost Savings in Development

While traditional tooling for mass production—especially for metals or large-scale injection molding—can be expensive and time-consuming, rapid prototyping enables cost-efficient exploration of multiple design iterations before committing.

Identifying flaws early and minimizing issues before production allows businesses to avoid unnecessary production ramps, change orders, and wasted materials.

Moreover, prototyping techniques like SLS or SLA are relatively moderate in cost while offering high-fidelity outputs, making them ideal for exploring material selection, surface finishes, and interactive components during the early stages of development.

The Rapid Prototyping Process Explained

What rapid prototyping looks like will vary depending on the product, manufacturing method, material, and more. However, whether it’s injection molding, silicone molding, or any traditional manufacturing methods, some basic key steps are always involved in creating functional prototypes.

Step 1 – Conceptual Design

The process begins with conceptual thinking, where teams map out product ideas through sketches, digital mockups, or interactive wireframes. Design systems and digital design libraries are typically used to ensure brand alignment and design consistency.

At this stage, prototyping software can rapidly create concept models or digital 3D models, often guided by AI-powered prototyping tools for layout, interaction, and user flow predictions.

Step 2 – CAD Modeling and Design Refinement

The next step involves translating these ideas into detailed CAD models using computer-aided design software. These CAD models serve as the basis for all downstream prototyping work, supporting tolerance calculations, material considerations, and simulations.

Proper attention to design for manufacturing (DFM) during this phase ensures that even the earliest prototypes are production-aware, avoiding changes in product development later on. Complex components, including inserts, fitments, or assemblies, are typically finalized here.

Step 3 – Physical Prototype Fabrication

With finalized digital models, engineers proceed to build physical prototypes using one or more rapid prototyping technologies, from SLA/SLS to 3D printing or CNC subtractive manufacturing.

Material selection also occurs here, with considerations around strength, flexibility, temperature resistance, or aesthetics depending on the intended use. Prototypes made from biodegradable materials, flexible polymers, or high-strength plastics can all be fabricated quickly with the right equipment.

Step 4 – Testing and Evaluation

Usability testing, field testing, and functional testing now take center stage. Teams evaluate everything from structural integrity to user interface behavior, noting areas for improvement.

Feedback from testing is critical for capturing insights that may affect form, features, materials, or user interaction. For complex designs, this step may be repeated several times with new prototype iterations, each refining the model toward the final product.

Step 5 – Iteration and Optimization

The final pre-production phase involves refining CAD models, updating the prototype layer, and revalidating new versions. Prototyping tools and simulation software can shorten this cycle dramatically by predicting performance and material behaviors digitally before the next fabrication round.

Some teams also conduct market testing with near-production models to assess customer response or validate ergonomics. This feedback loop helps de-risk full-scale manufacturing, especially when facing tight time-to-market deadlines or cost efficiency requirements.

Core Rapid Prototyping Techniques and Kenvox Capabilities

Rapid prototyping involves a range of techniques that accelerate product development and time-to-market. This section delves into the most effective methods, highlighting the capabilities and innovations offered by Kenvox to streamline and enhance the prototyping process. Whether prototyping with 3D printing, CNC machining, or advanced simulation tools, understanding these core techniques is essential for efficient and successful product design.

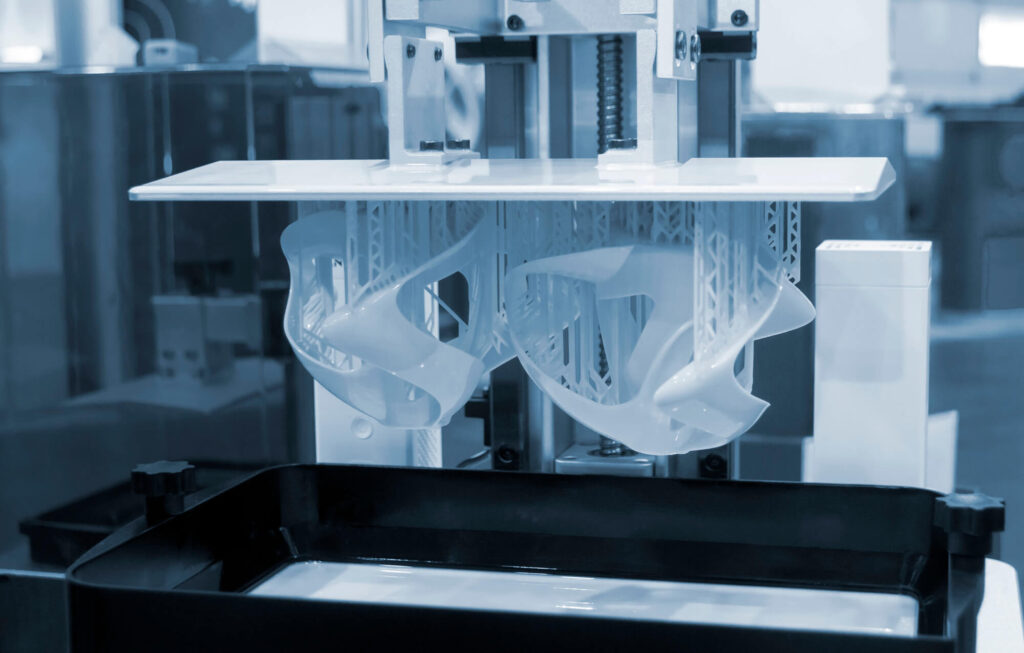

Additive Manufacturing (3D Printing)

Additive manufacturing, more commonly known as 3D printing, is the cornerstone of modern rapid prototyping. By building models layer by layer from digital 3D models, this method excels at quickly producing both concept prototypes and functional prototypes with moderate cost and excellent detail.

Kenvox leverages multiple 3D printing methods:

- FDM (Fused Deposition Modeling): Ideal for cost-efficient and quick visual validation.

- SLA (Stereolithography): Offers high-resolution surface finishes and tight tolerances, perfect for usability testing and design systems that require aesthetic accuracy.

- SLS (Selective Laser Sintering): Uses laser-based fusion of powdered materials for durable, load-bearing components, ideal for geometric prototypes and rugged field testing.

Whether you need to test interactive components or simulate material behavior in complex designs, Kenvox’s 3D printing fleet delivers speed, flexibility, and precision.

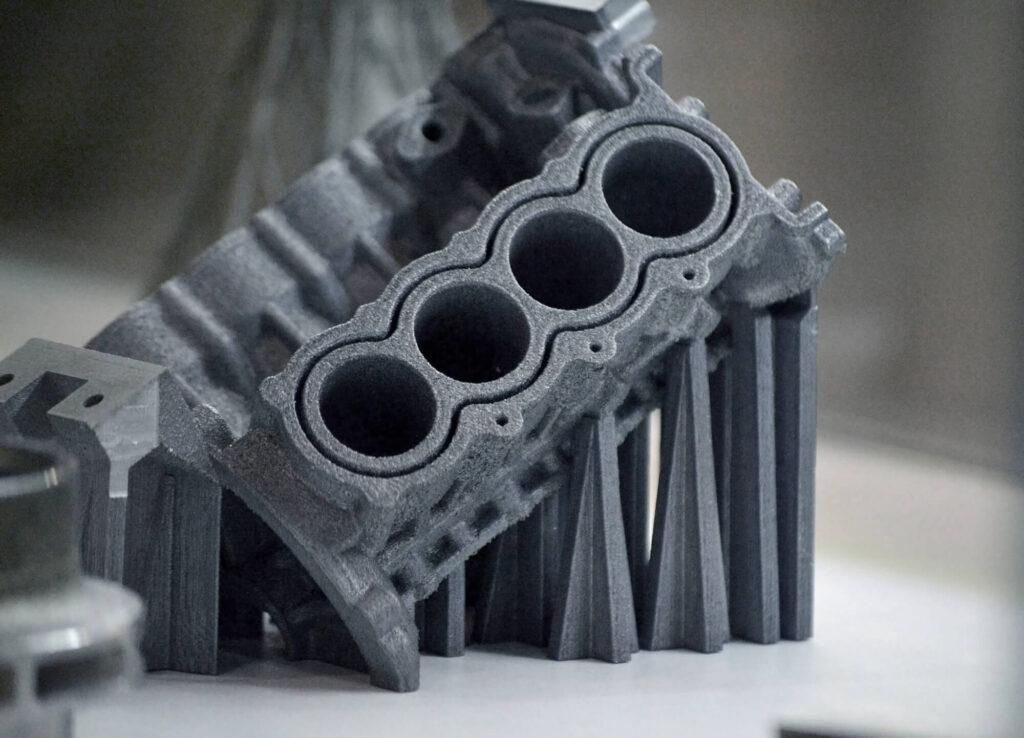

CNC Machining for Functional Prototypes

CNC machining remains the go-to for creating functional prototypes with real-world mechanical performance. Using advanced computer-controlled equipment, Kenvox produces accurate prototypes with tight tolerances in both metal and engineering-grade plastics.

This method is particularly valuable for later-stage prototypes that must simulate end-use production capabilities or meet strict dimensional tolerances. It is also the most reliable path for testing enormous titanium components, threaded assemblies, or parts where surface hardness and stress factors are critical.

From engineering product development to rugged industrial applications, Kenvox’s CNC capabilities support fast iteration and flawless execution, even under compressed development cycles.

Sheet Metal Prototyping

For prototyping structural components such as brackets, enclosures, and frames, sheet metal prototyping offers exceptional strength-to-weight ratios and design versatility. Using CNC laser cutting, bending, and forming techniques, Kenvox fabricates accurate physical prototypes in aluminum, stainless steel, and more.

These prototypes can be used in field testing environments or integrated into early production ramps to validate assembly processes, cable routing, or spatial geometry. This is especially valuable in sectors like automotive, consumer electronics, and aerospace.

Kenvox’s integrated prototyping services ensure that these sheet metal components align seamlessly with plastic or silicone parts for hybrid assemblies.

Silicone Molding for Prototypes

Kenvox is also an industry leader in rapid prototyping with silicone molding. This method is particularly effective for creating biocompatible, flexible, or soft-touch prototypes used in medical devices, wearables, and kitchenware.

By using techniques such as:

- Liquid Silicone Rubber (LSR) injection

- Solid Silicone Rubber (SSR) compression molding

- Room Temperature Vulcanization (RTV)

Kenvox can replicate complex components that would be difficult to prototype using rigid methods. These prototypes are often used for early user testing, touch-feel analysis, and iterative optimization of ergonomic elements.

More details on this are available in Kenvox’s previous blog post on silicone molding for prototyping.

Integrated Prototyping Efficiency at Kenvox

Unlike many contract manufacturers, Kenvox offers end-to-end rapid prototyping under one roof. From CAD models to prototype fabrication and testing, every step is managed via a proprietary ERP system, which provides real-time tracking, resource allocation, and cost oversight.

This integration translates to:

- Shorter development timelines

- Fewer production issues

- Improved communication across design and manufacturing teams

- Seamless transition from prototype to bridge tooling or mass production

Whether you need a physical prototype within 48 hours or are planning a series of complex prototypes for usability testing, Kenvox’s prototyping infrastructure ensures efficiency, scalability, and accuracy.

Applications Across Industries

Automotive

The automotive sector requires accurate prototyping of components that will ultimately face heat, vibration, pressure, and chemical exposure. Kenvox supports this with rapid prototyping technologies that produce gaskets, mounts, connectors, and housing prototypes using both CNC machining and silicone molding.

Functional testing is conducted on materials selected for specific conditions, enabling engineers to validate performance long before committing to full-scale production.

Medical

Prototyping in the medical field demands precision, biocompatibility, and compliance. Kenvox provides its medical device manufacturing customers with rapid prototyping using LSR molding and SLA 3D printing to support the development of surgical tools, wearable sensors, prosthetics, and diagnostic housings.

Using a range of materials—from flexible silicones to rigid medical-grade polymers—Kenvox helps medical innovators reduce the development timeline and gather feedback from testing, all while meeting regulatory demands.

Consumer Electronics

Prototyping for consumer tech is all about user experience, visual design, and functional integration. Kenvox produces concept prototypes and functional parts, including enclosures, buttons, soft-touch grips, and screen bezels, using SLA printing, silicone molding, and sheet metal techniques.

These prototypes allow design teams to validate assembly tolerances, UI component behavior, and user interaction during early testing phases, well before production ramps.

Industrial and Robotics

For industrial machinery, robotics, and automation tools, prototyping needs to simulate mechanical stress, moving joints, and rugged environments. Kenvox delivers complex prototypes in both plastic and metal, helping engineers validate mechanisms and component interfaces.

Large-scale metal housings, flexible joints, and integrated electronic shells are just a few examples of what can be created through Kenvox’s rapid prototyping process.

Aerospace

Aerospace prototyping often involves lightweight yet structurally critical components that demand extreme laser accuracy. Kenvox offers additive and subtractive processes to produce aerospace-ready prototype components, from aerodynamic shell sections to internal ducting and bracketry.

Materials like aluminum, titanium, and high-heat-resistant polymers are used to test the feasibility and manufacturability of complex parts before mass production.

Best Practices for Getting the Most from Rapid Prototyping

To maximize the effectiveness of rapid prototyping and ensure a smooth product development process, certain best practices should be followed.

Clarify Your Objectives Early

Before beginning any rapid prototyping process, it’s crucial to define what you’re testing or validating. Is it the form and aesthetics of a product, the functionality of complex components, or the behavior of materials under stress?

Clear objectives help determine the type of prototype required and inform decisions about prototyping tools, material selection, and production timeline. Defining your end goal reduces unnecessary iterations and avoids issues before production begins.

Choose the Right Method for the Right Stage

Different prototyping methods are suited to different stages in the product development cycle:

- 3D printing is ideal for early-stage concept models.

- CNC machining is better for later-stage prototypes that require mechanical testing.

- Silicone molding works well when flexibility or user testing is needed.

- Sheet metal is best for testing enclosures and structural parts.

Each method offers trade-offs between speed, cost efficiency, precision, and material properties. Aligning your method to your development stage ensures cost savings and testing relevance.

Engage a Manufacturer with Integrated Services

Working with a manufacturer like Kenvox, which offers in-house design systems, prototyping tools, and production services, eliminates friction between design, testing, and manufacturing. This is especially important in projects involving interactive components, moderate-cost materials, or complex assembly requirements.

An integrated prototyping ecosystem avoids delays in production, ensures consistency between prototype and final product, and provides end-use production capabilities without vendor handoffs.

Iterate Quickly, But Thoughtfully

Rapid iteration is a core benefit of prototyping—but too much iteration without focused goals can introduce waste and increase manufacturing costs. Each prototype layer should be evaluated with specific testing criteria tied to the product development process.

Gather feedback from testing teams, align your findings with the digital model or CAD system, and only proceed with redesigns when there’s clear justification. This keeps your development cycles agile while maintaining cost efficiency.

Why Choose Kenvox for Rapid Prototyping?

Kenvox isn’t just a prototyping vendor—it’s a vertically integrated, global manufacturing partner that brings design thinking, engineering, and production together under one roof. Whether you’re building your earliest prototype model or preparing for mass manufacturing, Kenvox accelerates your development with precision, advanced technologies, and a refined methodology that supports every stage of the life cycle.

Full-Service Prototyping from Concept to Production

Kenvox offers a complete suite of services that take your product from idea to physical prototype, and all the way through to large-scale production. Using advanced CAD modeling, workflow automation, and AI-powered rapid prototyping tools, Kenvox shortens the development timeline while ensuring accurate prototyping and cost control.

This includes access to 3D printing labs, stereolithography machines, silicone molding workshops, CNC machining centers, metal fabrication units, and industrial design teams. With these prototyping technologies and classification methods available in-house, clients can move from wireframe sketch to functional prototype without switching vendors.

Kenvox also maintains extensive design libraries, software-driven process optimization systems, and real-time ERP integrations that track every process step and cycle, creating a smooth flowchart from early concept to final approval.

Fast Turnaround Times with ERP Precision

Time is a critical factor in competitive product development. Kenvox’s internal ERP and PDM systems monitor every stage of the rapid prototyping process with extreme accuracy. Each step of the workflow is tracked using digital thread principles, ensuring predictable scheduling, reduced errors, and fast decision-making throughout the prototyping cycle.

This agile approach allows engineers to refine products rapidly and supports teams who require iterative prototypes, block diagram adjustments, or updated model variations. Kenvox helps clients hit aggressive launch dates without sacrificing quality.

Global Manufacturing, Local Support

Kenvox operates high-tech manufacturing facilities across China and Vietnam, along with a U.S.-based communication hub in California. This operational model allows for global scalability and regional responsiveness.

Clients benefit from real-time support, faster feedback loops, and smoother collaboration regardless of where they are located. Whether you require updates to your cardboard mockup, a revised industrial design sketch, or a new prototype version, Kenvox’s project teams provide hands-on assistance across every phase of the SDLC-inspired product development process.

Experience Across Materials and Methods

With more than three decades of experience, Kenvox works with a wide range of materials—from biodegradable polymers and soft-touch silicones to aerospace-grade metals and engineering plastics. These capabilities ensure that your product benefits from the optimal prototyping technologies and manufacturing techniques available.

The engineering teams are versed in a variety of techniques including injection molding previews, CNC machining prototypes, stereolithography resin builds, and 3D printing for early design exploration. This breadth of experience ensures every prototype is ready for usability testing, field evaluation, or full-scale production validation.

Their engineers, designers, and technicians collaborate closely to ensure that each product flows through every life cycle stage—concept, modeling, prototyping, and manufacturing—without disruption.

The Next Steps with Kenvox

Rapid prototyping is no longer optional in modern development. It reduces risk, enhances innovation, and shortens development cycles by enabling teams to rapidly transform a digital model into a physical prototype. It also supports design thinking principles by allowing early testing and feedback, improving the product before it reaches the final production phase.

With the right partner, you can confidently transition from concept prototypes to functional prototypes—and from small batch testing to full-scale manufacturing—while maintaining high product quality, controlled costs, and predictable timelines.

Kenvox delivers a powerful combination of precision engineering, integrated services, and global manufacturing scalability. From prototyping technologies to cost-efficient production ramps, Kenvox helps companies accelerate innovation without compromising on quality or speed.

Contact Kenvox today for a consultation, or send us your digital 3D model for a feasibility review. Let’s bring your next big idea to life, faster, smarter, and stronger.