Every product starts with a spark, which can be an initial concept drawn from market research, customer feedback, or a bold idea on a whiteboard. But bringing that concept to life in physical form takes more than putting together parts.

It’s really about crafting prototype models that can evolve into successful, scalable products. This is where selecting the right prototype partner becomes a mission-critical decision in your product development process.

From early concept validation to full-rate production, an experienced prototype partner ensures that your prototype design not only looks good in CAD models but is also actually manufacturable, testable, and aligned with your long-term market goals.

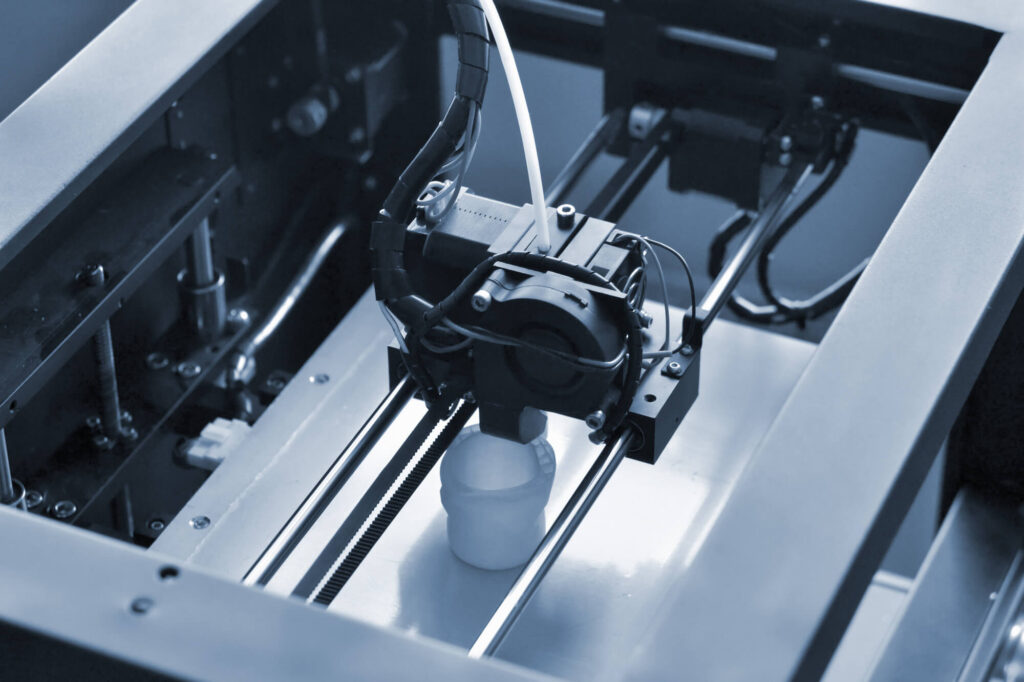

At this stage, speed, precision, material compatibility, and design for manufacturing (DFM) must converge seamlessly. Whether you’re working with 3D printing, Injection Molding, Urethane Casting, or CNC machining, the right partnership transforms complexity into clarity.

In this guide, we’ll break down the essential stages, expectations, and pitfalls to avoid when engaging a contract manufacturing partner for prototyping, so your next big idea doesn’t just make it to market, but dominates it.

Why Choosing the Right Prototype Partner Matters

Choosing a prototype partner is, above all else, about an alignment with your design thinking, engineering goals, and target industry. It shouldn’t matter if you’re developing medical devices, consumer goods, or components for the automotive or aerospace industry; your partner must offer product fluency.

Here’s why it matters:

- A true prototype partner helps bridge the gap between industrial design and manufacturing. That means interpreting CAD (Computer-Aided Design) files not only from a design lens but also for hardware-to-material compatibility.

- They provide insight into material selection, optimizing for mechanical performance, aesthetics, and compliance (e.g., ISO 9001, IPC-2581).

- The right partner shortens your new product introduction (NPI) cycle through rapid prototyping, DFM feedback, and testing procedures, reducing revision loops and accelerating market success.

- Strong partners bring access to a material library, digital twin simulations, and even metal prototyping services—from overmolding and insert molding to sheet metal fabrication and metal finishing—ensuring each part is built for both form and function.

At Kenvox, for example, the combination of a vertically integrated manufacturing space, seasoned engineering staff, and dedicated QA systems delivers end-to-end continuity.

We don’t just build prototypes: we build functional prototypes engineered for scalability, from weld fixtures to impedance-controlled traces.

The Prototype-to-Production Journey

Successful prototype manufacturing follows a defined path that balances creativity with constraint and experimentation with engineering discipline. Each stage is critical, and missteps can lead to rework, delays, or cost blowouts in full-rate production.

1. Initial Concept & Engineering Feasibility

This is where teams working to design & engineer begin turning ideas into workable CAD models. An experienced prototype partner will ask questions about components, use cases, user expectations, and sustainable product design principles. Here, Thomas Edison’s approach rings true: “To invent, you need a good imagination and a pile of junk”—but that imagination needs a clear path to manufacturability.

Best practices:

- Engage cross-functional teams (mechanical, electronics design, software, and firmware development)

- Perform early design phase reviews for DFM risks

- Identify primary manufacturing methods: 3D Printing, CNC machining, Sheet Metal Fabrication, among others.

2. Material and Method Selection

Every great prototype design needs a sound material selection strategy. This is where hardware-to-material compatibility becomes vital, especially in multi-material builds. The wrong choice here creates testing bottlenecks or scalability issues later on.

What to expect from a prototype partner:

- Recommendations based on DFM feedback, thermal stress, finish quality, and use case

- Access to a deep material library for plastics, metals, and elastomers

- Alignment of materials with manufacturing methods such as injection molding, overmolding, or additive manufacturing

3. Prototype Manufacturing

This is the heart of the partnership and where your idea becomes physical. Depending on your goals, your partner might use visual prototypes (for stakeholder approval or ergonomics testing) or functional prototypes (to simulate mechanical or environmental performance).

Common technologies include:

- Additive Manufacturing for fast turnaround

- CNC machining for precision components

- Urethane Casting for low-run elastomeric parts

- Insert Molding for embedded electronics

- Sheet Metal Fabrication for structural prototypes

4. Testing & Validation

Every prototype should be tested not only for fit and function but for future manufacturability. Your partner should run testing procedures aligned with your quality targets, whether you’re validating impedance traces for electronics or mechanical load cycles for seating systems.

Checklist:

- Functional testing under real-world conditions

- Conformance to quality management systems like ISO 9001

- QA protocols with data capture: thermal analysis, part tolerances, cycle times

Key Services You Should Expect from a Prototype Partner

A capable prototype partner should be more than just a vendor; they should be a strategic partner. See them, and use them, as a strategic extension of your product team. The more integrated their services, the more streamlined your product development lifecycle will be. Here’s what a world-class partner should offer:

Rapid Prototyping Technologies

In early-stage development, speed matters, but not at the expense of accuracy or viability. That’s where rapid prototyping comes in, offering accelerated timelines with meaningful outputs. Whether you’re validating fit with visual prototypes or stress-testing functional prototypes, expect a suite of flexible technologies.

Key capabilities to look for:

- 3D printing and additive manufacturing for design iterations and multi-part assemblies

- CNC machining for tight-tolerance mechanical parts, especially in the aerospace and automotive sectors

- Insert molding and overmolding for hybrid components, such as embedded sensors or overlaid soft-touch finishes

- Sheet metal fabrication for enclosures, frames, and early-stage load-bearing tests

The ability to pivot between technologies is key, especially as early assumptions evolve. At Kenvox, all of these services are available under one vertically integrated roof, enabling faster decisions without vendor delays.

Material Expertise

Material choice influences everything from manufacturing method to testing protocol. A true prototype partner provides material consultation, and not just a dropdown menu of stock options.

They’ll guide you through:

- Selecting between thermoplastics, silicones, or metals based on project needs

- Evaluating surface finishes, thermal resistance, or bio-compatibility

- Aligning material properties with later-stage injection molding, welding, or metal finishing

- Using simulation tools to predict material behavior under load, heat, or assembly processes

This process isn’t trial and error, but data-driven. A partner should maintain a curated material library, complete with data sheets and performance histories across industries.

Design for Manufacturability (DFM) Insights

Many designs that look flawless in CAD models encounter real-world issues during manufacturing, such as undercuts, unsupported walls, or impractical draft angles. This is why DFM feedback is essential.

Expect your partner to:

- Analyze models for tolerance stack-ups, parting lines, and moldability

- Suggest geometry optimizations to reduce tooling complexity and cost

- Provide documentation tied to DFM reviews, ideally integrated into your version control system

Whether you’re designing a seating system for a vehicle or a sensor housing for medical use, these checks reduce iterations and make sure each revision gets closer to production-readiness.

Manufacturing Method Alignment

Different prototype designs call for different manufacturing methods, and the wrong pairing creates downstream risk. A strong prototype partner will map your prototype design to scalable production techniques early in the process.

The goal is NPI readiness, making sure your prototype manufacturing path feeds directly into full-rate production without requiring major redesigns.

Costs, Timelines, and Communication Best Practices

When partnering for prototyping services, transparency must be a core competency. And not just a courtesy. Budget overruns and timeline slippage often stem not from bad intentions but from poor alignment and incomplete communication.

Here’s what best-in-class looks like:

Understand the Cost Drivers

Your prototype partner should break down cost not only by line item, but by decision layer.

What impacts pricing:

- Materials: Commodity vs. performance-grade polymers or alloys, etc.

- Manufacturing method: CNC machining, sheet metal, 3D printing, Rim and SLA, and more.

- Post-processing: Secondary processes like metal finishing, painting, laser engraving, or secondary assemblies

- Volume: Are you creating one visual prototype or 20 functional prototypes for pilot testing?

Expect a clear, itemized quote with optional paths. Partners who integrate digital manufacturing tools often provide dynamic pricing models tied to live DFM feedback.

Expect Agile Timelines, Not Just Promises

Speed should never sacrifice repeatability. A reliable partner delivers on tight timelines by optimizing workflows, not just by rushing jobs.

Timeline best practices:

- Establish phase-based milestones: CAD freeze, prototyping, QA, pilot run

- Build in time for engineering change orders without resetting the clock

- Ensure physical testing is included before sign-off

Communication as a Competitive Advantage

Clear communication makes your prototype journey predictable. This means more than emails. You must receive structured updates, shared documentation, and be informed about escalation protocols.

Best practices include:

- Dedicated PMs or engineering staff contacts per project

- Integrated communication across time zones (especially with global manufacturing partners)

- Visibility into quality control data, impedance-controlled traces, IPC-2581 compliance, and tooling updates

The bottom line: transparency builds trust. And trust accelerates innovation.

Use of Useful and Transparent Metrics

Choosing the right prototype partner means looking past marketing decks and into measurable performance. Great partners don’t hide behind jargon; they show their numbers.

Here are the metrics that matter most:

- First-pass yield

- Prototype turnaround time

- Revision traceability

- Quality audit success rate

Ask your partner to share historical KPIs and case studies across industries like aerospace, consumer goods, and electronics design.

Avoiding Common Pitfalls

The prototyping phase is where foundational errors often get locked in—errors that multiply in full-rate production. Knowing what to watch for will save months of rework.

Common pitfalls and how to avoid them:

- Skipping early DFM analysis

Risk: Tooling changes, failed prototypes

Solution: Require a DFM report before prototype build begins - Choosing a single-service vendor

Risk: Gaps between design, metal prototyping services, and injection molding stages

Solution: Select a vertically integrated partner with digital manufacturing depth - Underestimating testing needs

Risk: Late-stage part failure, field returns

Solution: Build a testing procedure plan with both simulated and physical validation - No IP or data governance in place

Risk: Leaked CAD files, exposed patent support materials

Solution: Use partners with secure data environments and legal NDA frameworks - Lack of regional production flexibility

Risk: Tariff exposure, delivery delays

Solution: Leverage dual-site models like Kenvox’s operations in China and Vietnam

Even experienced product teams fall into these traps without a structured approach. Your prototype partner should proactively flag these risks and present mitigations, not just respond after issues arise.

The Kenvox Advantage: Prototype to Production in One Ecosystem

Kenvox is a global contract manufacturing ecosystem built to turn complexity into speed, not just a factory. Our clients range from emerging startups to Fortune 500 OEMs across automotive, consumer electronics, medical, and industrial equipment sectors.

Kenvox integrates proprietary algorithms and project dashboards to synchronize scheduling across in-house machining, molding, and finishing teams. Our clients can monitor real-time progress, validate testing procedures, and adapt fast when market demands shift.

What sets Kenvox apart:

- Integrated manufacturing space: From 3D printing to sheet metal fabrication, all under one roof

- Multisite manufacturing: Dual-site strategy (China + Vietnam) for capacity, cost control, and risk mitigation

- Certified QA infrastructure: Compliance with ISO 9001, ISO 13485, and IATF 16949

- DFM-based workflows: Every prototype model is vetted against our proprietary DFM playbook and real-world production benchmarks

- Proven IP safeguards: Secure platforms for file sharing, version control, and IPC-2581 standard alignment

- Scalable services: From low-volume visual prototypes to high-volume molded assemblies with multi-material configurations

Because we manage material selection, design translation, manufacturing methods, and QC in-house, your product doesn’t change hands; it evolves with precision.

Turn Prototypes Into Market-Ready Products

From Thomas Edison’s tinkering bench to today’s AI-assisted CAD (Computer-Aided Design) labs, the path from idea to product has always hinged on execution. Your prototype partner plays a crucial role in determining whether your product launches on time or lags behind competitors.

At Kenvox, we offer end-to-end visibility, a team of tested engineers, advanced digital tools, and world-class prototyping capabilities. More importantly, we offer peace of mind.

Start Your Prototype with Confidence

Ready to turn your vision into a manufacturable reality? Kenvox offers rapid quotes, transparent production plans, and hands-on support through every stage of your prototype manufacturing journey.

With Kenvox, you bring the concept, but we’ll bring the clarity, capability, and speed.

Request your custom prototype quote today. Let’s build something that lasts.