MOLD, PLASTIC, SILICONE,

METAL & COMPLEX PRODUCTS

MOLD, PLASTIC, SILICONE,

METAL & COMPLEX PRODUCTS

Kenvox is an OEM contract manufacturer which has developed and currently produce over 200 unique projects annually. We have a signed NDA with 95% of our customers which prevents us from showcasing their products. The items shown here are very common and represent a simplified sampling of our capatabilities.

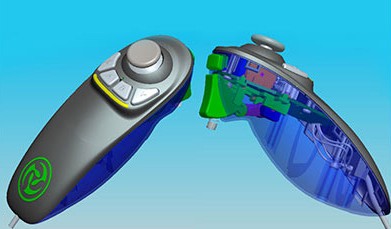

This gaming device uses high performance inertial sensors to provide 360 degrees of low latency, real-time motion tracking without the need for cameras or optics. The device allows for multiple simultaneous users. It works indoors and outdoors, in capture spaces of any size.

The suits include two hand-controllers with action buttons, triggers and joysticks. The joysticks let you navigate easily through large worlds without actually walking, while the triggers supports a familiar shooting experience.

Kenvox was involved with this project’s development from the beginning when it was a rough idea. We are able to help our customers overcome designing/manufacturing issues with plastic, mechanical, fabric, and cable parts.

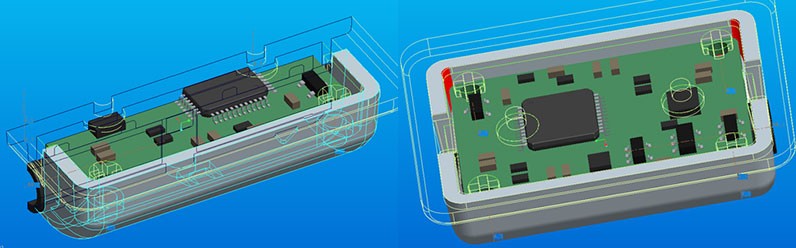

1.Help to refine and finalize structure design

1.1 Problems Kenvox helped customer solve:

Figured out how to assemble the lighting bar on the top controller cover to provide the best lighting effect. Also figured out the easiest way to assemble the part with the lowest manufacturing cost.

1.2 Problems Kenvox helped customer solve:

Kenvox helped to simplify assembly, save on mold cost and improve productivity.

1.3 Problems Kenvox helped customer solve:

The customer updated the PCBA, which caused the plastic mechanical parts to affect the electronic components, creating assembly problems. Kenvox helped the customer work the modifications out and offered a solution to solve the new issues, without changing the appearance. Mold cost was not increased.

2. Helped refine/finalize the fabric design

The customer just had rough drawings of what they wanted, but Kenvox helped to design and make a high functioning prototype.

2.1 Helped refine/finalize the fabric design

The original cable jacket head had a very thin plastic wall. During production, the welding spot has a high probability of being broken when the cables are compressed into the mold. We were able to complete this difficult process and satisfy our customer’s requirements.

Copyright © Kenvox Industrial Group all rights reserved.