MOLD, PLASTIC, SILICONE,

METAL & COMPLEX PRODUCTS

MOLD, PLASTIC, SILICONE,

METAL & COMPLEX PRODUCTS

Kenvox is an OEM contract manufacturer which has developed and currently produce over 200 unique projects annually. We have a signed NDA with 95% of our customers which prevents us from showcasing their products. The items shown here are very common and represent a simplified sampling of our capatabilities.

This is a pedal powered washing machine that uses minimal amounts of water and no electricity.

Features:

Quick and easy to use

Small, compact, and portable

Water-saving and no electricity required

Only takes 5 – 10 minutes per load

Uses 80% less water than standard washing machines

The client spent over three years in Canada to create the initial design. Three versions of the ready-to-test prototype were created, but still did not have a final manufacture CAD drawing.

Searched China to find the proper company to help realize their design and find a manufacturer. They visited and audited over 12 different sized factories in China.

Kenvox was selected as the final vendor to handle the entire project. After auditing our factory, this client was pleased with our project engineer’s professionalism and Kenvox’s ability to perform the project at a reasonable cost.

Kenvox identified a lot of potential manufacturing issues with their CAD model. A special project development team was assembled to perform a case study. After many meetings and negotiations, they allowed us to make modifications and refine their entire CAD model.

It took 6 engineers over a month to simply the product from 250 parts down to 150 parts. These changes resulted in significant cost savings on both the mold and materials.

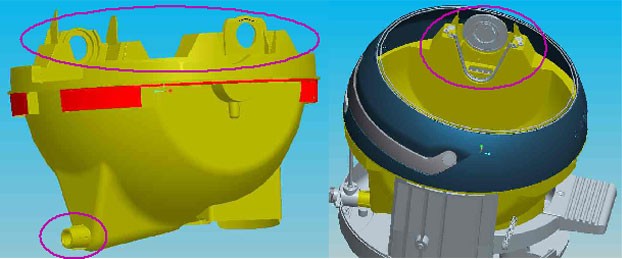

NO.1

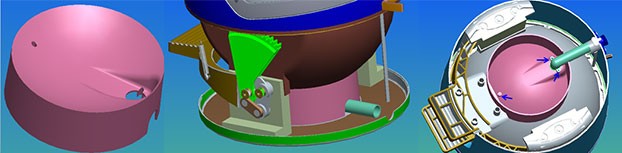

A new mold was needed because the original would not allow the whole design to be produced. The structure was unreasonable and affected the product’s ability to form a proper water seal.

After Kenvox modification:

Kenvox removed the two holes on the top ears and replaced the horizontal water drain holes with vertical ones. Overall structure was enhanced and the water seal function was improved.

NO.2

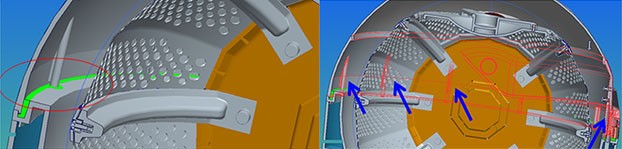

Kenvox helps to add ribs to enhance strength of the major mechanical part.

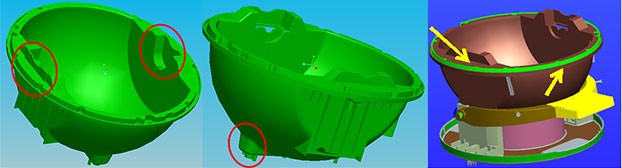

NO.3

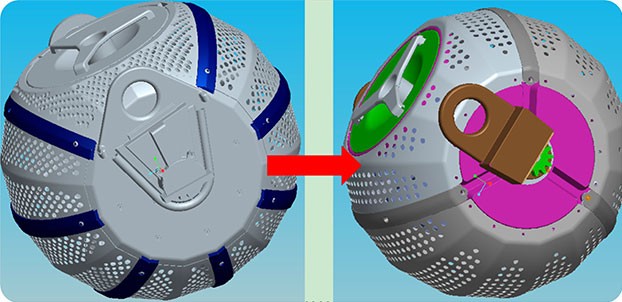

Helped to simplify the locking system on the top lid, saving 1 metal ring and 2 plastic blocks reducing a significant amount on mold and production costs. The end result also improved the locking system making it more stable and easier to operate.

NO.4

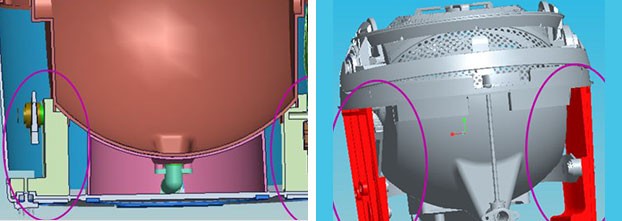

Added the pink support to the base to reinforce the heaviest part of the product, ensuring the product would not collapse or break during the washing process.

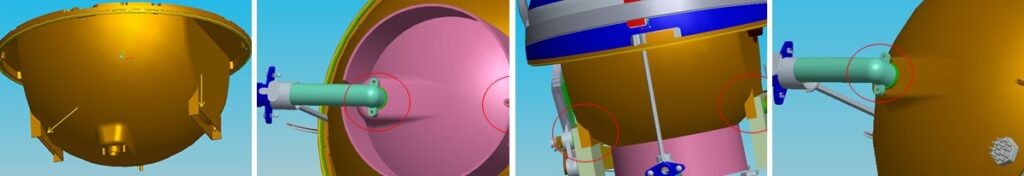

NO.5

Simplified the two aluminum struts on both sides. This saved on mold and product cost. This change also reduced the weight of the whole product, saving on shipping cost.

NO.6

Improved the structure by making the spherical drum from 3 sheets of metal instead of 6, simplifying the assembly process and saving labor cost

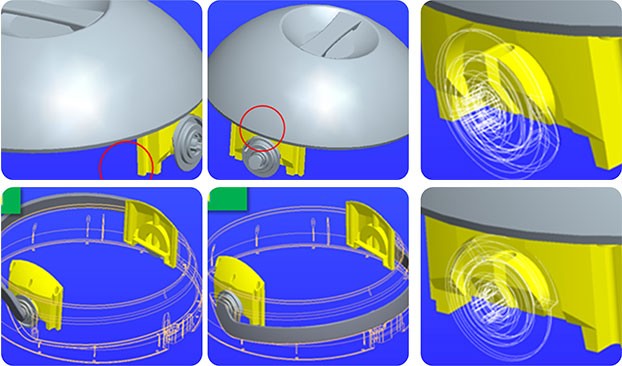

NO.7

In the original design the upper dome was assembled using an adhesive. This would not be ideal for long term use. Kenvox created a new design with bosses so the upper dome could be assembled with screws, significantly improving structural integrity.

NO.8

Many modification details needed to be discussed throughout this project. We were able to make these modifications successfully through great communication between the client and ourselves. Clients were impressed with our ability to handle the project and were happy with their product.

Kenvox’s project team includes a sales rep, senior sales manager, procurement staff, structural engineer, drawing engineer, production engineers and tooling engineers. The single team focus is to provide a seamless integration of customer ideas and requirements into the product.

Kenvox is proud to have such diligent staff that does not go unnoticed by our customers.

Copyright © Kenvox Industrial Group all rights reserved.