MOLD, PLASTIC, SILICONE,

METAL & COMPLEX PRODUCTS

MOLD, PLASTIC, SILICONE,

METAL & COMPLEX PRODUCTS

Kenvox is an OEM contract manufacturer which has developed and currently produce over 200 unique projects annually. We have a signed NDA with 95% of our customers which prevents us from showcasing their products. The items shown here are very common and represent a simplified sampling of our capatabilities.

This device was designed by an Australian company who was referred to Kenvox by another customer. The first generation of this device was produced by a Singaporean factory. The device did great in sales but quality was lacking due to multiple flaws in deign and inproper manufacturing technology. A new generation of the device was designed with a complicated double-shot injection method. Many factories around the world were considered for this project but none met the desired qualifications. When Kenvox was introduced, a week long on-site investigation and audit commenced and was deemed capable of meeting this company’s requirements. Kenvox was able to overcome many technical and manufacturing difficulties to satisfy the customer.

This device is a wireless headset that monitors your brain activity and translates EEG into meaningful data you can understand.

This sleek 5-channel wireless EEG headset is mostly used by people who use wheelchairs.

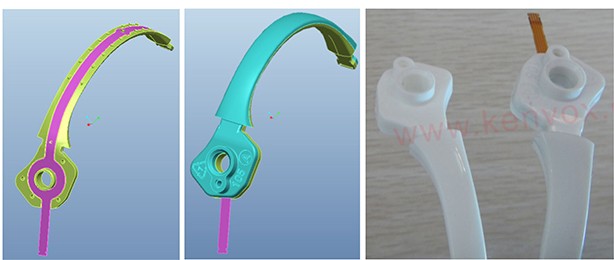

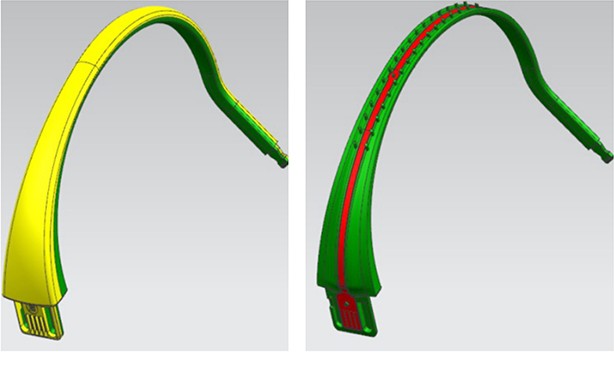

This product contains a total of 24 different pieces, including plastic, metal, silicone, PCB and FPCB. One of the biggest difficulties with this project was the double-shot injection molding for the arms, which contains an FPCB inside. The FPCB had a very high defect rate due to breakage during injection. After several tests, Kenvox came up with the solution of making small holes for the FPCB and applying an adhesive to hold it in place during the injection.

Complicated assembly process requiring high precision, yielding a high defect rate that was difficult to control at each process.

High gloss surface finish which is easily damaged during post processing.

NO.1

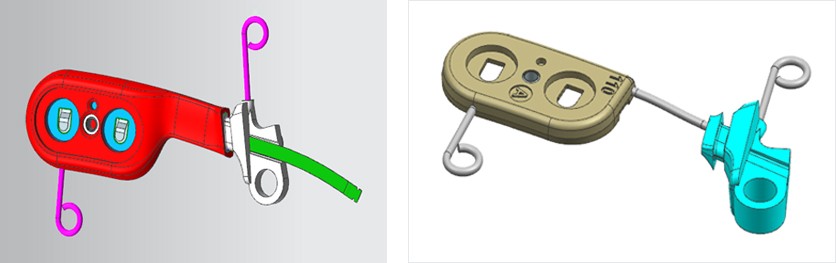

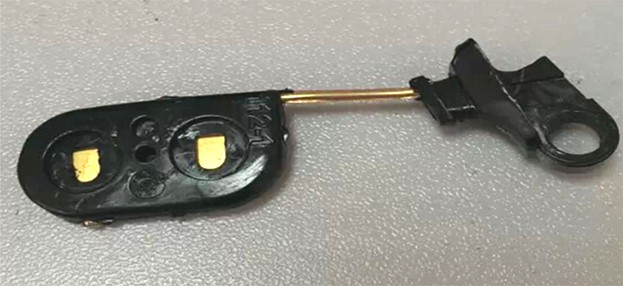

Copper sheet instered into the mold requiring high accuracy. Misplacement would result in a broken mold.

NO.2

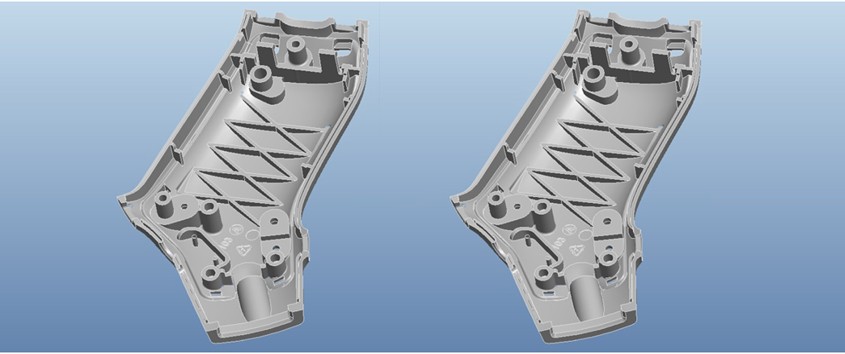

The housing is a high glossy SPI-A2, which requires an imported, high cost, steel for the mold. There are three side lifter systems in the mold to make holes, side fillets, etc. Once the mold process is finished, copper nuts and metal sheets will be assembled into the part.

NO.3

Helped to simplify the locking system on the top lid, saving 1 metal ring and 2 plastic blocks reducing a significant amount on mold and production costs. The end result also improved the locking system making it more stable and easier to operate.

The most difficult step in making this part is the over-mold on the copper wire. The copper wire could not be exposed or flattened making this a difficult requirement to meet. The copper wire is a high cost material and any attrition would would make this product cost prohibitive.

NO.4

These parts were made with a double shot injection machine. The body is a rigid plastic and the rest is a soft TPE.

The over-mold parts require a strong bond, accurately placed, and cannot overflow onto the rigid parts.

NO.5

This PCB needs to be accurately over-molded, so it won’t be exposed in order to meet the customer’s requirements. We had to make sure the PCB did not deform or break during the molding.

NO.6

The production of the arms was the most difficult part of this project. They were made through the double shot molding process, which only a few factories in China can do. The molds had several slider systems. The sliders were ejected from many different directions, which required a complicated structure and a high precision mold.