Any business or entrepreneur that offers a product in today’s hyper-competitive global market without factoring in the realities of the manufacturing process is setting itself up for budget overruns, delays, and avoidable product failures. Too often, companies treat manufacturing as an afterthought; they only engage engineers and manufacturing teams once the product design is finalized. This disconnect between design and execution results in increased manufacturing costs, excessive material waste, longer timelines, and ultimately, reduced product quality.

The culprit? A lack of Design for Manufacturability (DFM) strategy during the early product development process.

Design for Manufacturability is an engineering and design approach that aligns product development, materials, assembly methods, and manufacturing constraints from the outset, allowing companies to achieve substantial cost savings, reduce assembly errors, and enhance operational agility.

This guide will explore and explain how DFM transforms the entire product development cycle, saving thousands in rework and waste, and why companies that embrace it early gain a serious edge in time-to-market, efficiency, and profit margins.

What is Design for Manufacturability (DFM)?

Design for Manufacturability (DFM), or Design for Manufacturing, refers to the practice of designing products in a way that simplifies and optimizes the manufacturing process, without compromising functionality or performance. It’s about making sure your product is not only innovative but also efficient to produce, easy to assemble, and reliable in the field.

While it might be obvious to many outside of the manufacturing industry, the reality is that producers frequently underestimate the complexities of the manufacturing process, which is why, at its core, manufacturing design is a bridge between theoretical product design and the practical world of manufacturing methods. It ensures the manufacturing team can produce your product at scale, with consistent product quality and minimal waste.

DFM vs. Design for Assembly (DFA)

While DFM focuses broadly on optimizing all manufacturing processes, including material selection, tooling, and part geometry, Design for Assembly (DFA) narrows in on how efficiently components come together during the assembly process on the manufacturing floor. Both approaches complement each other and are often combined into a holistic DFM/DFA methodology.

A well-executed DFM/DFA strategy reduces:

- Material Waste from poor material selection or incompatible design tolerances

- Manufacturing Constraints that make parts difficult or costly to produce

- Assembly Errors caused by unclear joins or incompatible components

- Manufacturing Challenges such as tight tolerances, multi-part joins, or tool misalignment

Why DFM is Critical in the Product Development Lifecycle

Incorporating DFM during the early product development cycle, rather than retrofitting it after prototyping, is vital. It prevents costly redesigns, reduces iteration loops, and allows for optimized choices between injection molding, additive manufacturing, or other manufacturing methods based on cost, volume, and materials.

When aligning engineering design with real-world manufacturing constraints, teams can:

- Accelerate the product development process

- Reduce manufacturing costs through smarter material selection and process planning

- Deliver consistent, high-quality products with fewer production issues

Ultimately, DFM is not just about saving money but about building faster, better products.

How DFM Influences Each Stage of Product Development

Integrating design for manufacturability into the product development process isn’t a one-time task. It’s better to see it as a methodology that shapes each critical phase of development. From concept to completion, DFM minimizes friction between design intent and real-world manufacturing constraints.

Material Selection

Choosing the right materials is one of the earliest—and most impactful—decisions in the product development cycle. Material selection directly affects manufacturing costs, material waste, product quality, and compatibility with manufacturing methods such as injection molding or additive manufacturing.

Without a DFM lens, teams often select materials based on design or aesthetic preferences alone, ignoring how those materials behave under pressure, temperature, or during the assembly process. This disconnect can lead to excessive wear, production delays, or the need for expensive retooling.

With DFM, the result is fewer material issues during production and a smoother path from prototype to mass manufacturing.

Design & Prototyping

The design and prototyping stage is where DFM delivers exponential value. During early iterations, design teams can optimize component geometries for manufacturability, such as uniform wall thickness for injection molding, or minimized support structures in additive manufacturing.

Without DFM, prototypes may look functional but fail when subjected to the rigors of real-world manufacturing processes. Issues like thin walls, complex internal cavities, or inaccessible undercuts can dramatically increase tooling costs or make components unmanufacturable.

Tooling & Manufacturing Methods

Once the design is finalized, tooling becomes the gateway to scaled production. DFM ensures that parts are designed with realistic tooling capabilities in mind, whether using high-volume injection molds or agile additive manufacturing techniques.

Designing for the capabilities of specific manufacturing methods leads to streamlined tool paths, faster setup times, and better overall process reliability.

Examples of How DFM Leads to Cost Reduction

The most compelling reason to adopt design for manufacturability is simple: it saves money. And not just pennies—strategic DFM decisions can lead to thousands (even hundreds of thousands) in long-term savings across manufacturing and assembly.

Here are some realistic scenarios, based on Kenvox’s years of experience with client products, on how DFM achieves this:

- Material Optimization Reduces Cost and Waste: A manufacturer working with silicone-based medical components initially used a high-grade elastomer that was not optimized for the selected molding process. Through DFM consultation, the team revised the material selection, switching to a more compatible and cost-effective compound without compromising product quality. This shift cut raw material expenses by 18% and reduced rejection rates by 22%, significantly impacting bottom-line results.

- Assembly Error Reduction via Design Simplification: In another case, a consumer electronics product required multi-step assembly across several parts. By applying DFM and design for assembly principles, engineers reduced the number of fasteners, introduced snap-fit joints, and simplified component alignment. This reduced total assembly time by 35% and slashed labor costs, all while improving structural integrity and reducing failure rates during quality checks.

- Tooling Streamlining for Injection Molding: A client preparing for high-volume production realized, late in the cycle, that their part design lacked proper draft angles for easy ejection from molds. Redesigning the tooling would have cost over $40,000. However, through early DFM intervention, the team adjusted geometries and harmonized tolerances with the tooling specs. Not only did this save the client the tooling cost, but it also avoided a 4-week delay in production.

These scenarios highlight what’s possible when manufacturing teams and design teams collaborate from the beginning. It’s not just about avoiding mistakes but about engineering success into the entire product development process.

Common Manufacturing Challenges DFM Solves

In a perfect world, product designs would flow effortlessly into production. However, in reality, manufacturing is full of hidden pitfalls. Many of these challenges arise not from the manufacturing process itself, but from a lack of coordination between the design and manufacturing teams.

Design for Manufacturability directly addresses these disconnects, proactively solving problems before they impact the production line.

- Misalignment Between Design and Manufacturing Teams: One of the most common issues in product development is when designers create components without fully understanding how they will be manufactured. This misalignment often leads to over-engineered features, complex geometries, and unrealistic tolerances that complicate manufacturing methods.

- Unnecessary Complexity in Assembly: Poorly designed parts often require complicated assembly methods, increasing the likelihood of assembly errors. For example, a design may require several fasteners where a snap-fit or integrated joint would suffice. Or components may be arranged in a way that requires excessive repositioning, increasing assembly time and labor.

- Excessive Material Waste: Designing without considering available materials or manufacturing constraints often results in material waste, such as excessive trimming in injection molding or redundant support structures in additive manufacturing. DFM will lead to less scrap, better yields, and more sustainable production practices.

- Late-Stage Redesigns: Perhaps the most costly challenge is discovering, after tooling or prototyping, that a design simply cannot be manufactured without significant changes. These late-stage redesigns can delay the product development cycle by weeks or even months and result in additional expenses that were never part of the original plan. DFM shifts this realization to the front of the process, where adjustments are fast, flexible, and cost-effective.

Kenvox’s Integrated Team Approach Through DFM

DFM must be viewed as a collaborative philosophy that brings together the talents of engineers, designers, and manufacturers under a unified goal: to build better products, faster.

At Kenvox, this cross-functional model is deeply embedded in every project.

Bridging Silos for Better Outcomes

In traditional workflows, product development and manufacturing exist in silos. Designers pass their work to the manufacturing team with little feedback, and issues only surface once production starts.

With DFM, Kenvox breaks this cycle by fostering early and frequent communication across departments.

- Multidisciplinary PMs: Dedicated project managers lead multidisciplinary teams from concept to completion, ensuring that product design, manufacturing processes, and quality control are aligned from day one.

- Advanced ERP: Our proprietary ERP system tracks every stage of the project, providing real-time visibility, traceability, and oversight. This not only prevents miscommunication but also empowers faster iterations, streamlined approvals, and reduced risk of costly oversights.

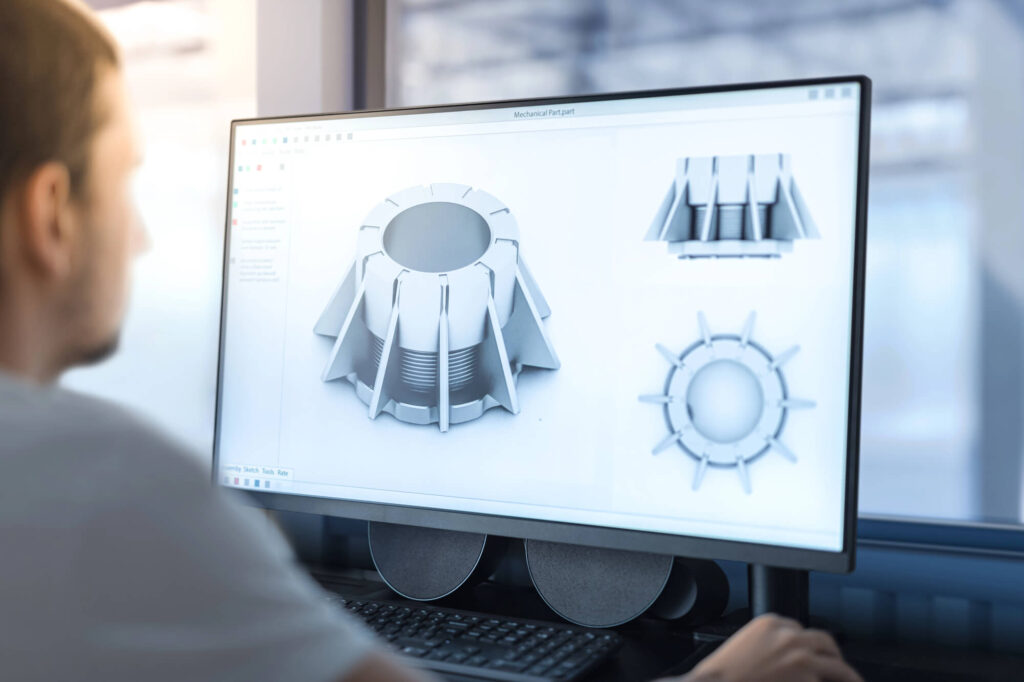

- Collaborative DFM Reviews: Kenvox engineering teams work closely with clients during the DFM review phase, analyzing CAD models for potential manufacturing constraints and assembly issues. This feedback loop allows clients to refine their designs with real-world manufacturing knowledge, reducing the risk of delays and improving final product quality.

The result? Seamless handoff from design to production, shorter lead times, and optimized manufacturing efficiency, all driven by the power of collaboration.

Best Practices for Implementing DFM

Design for Manufacturability should be a mindset in order to fully unlock its benefits, integrated early, systematically, and collaboratively throughout the entire product development process. The following best practices ensure that DFM becomes a powerful lever for cost savings, improved product quality, and manufacturing efficiency.

Start DFM at the Concept Phase

The biggest DFM mistake? Waiting too long. Many teams introduce DFM only after finalizing prototypes or selecting materials. However, by then, design changes are costly and time-consuming.

Instead, embed DFM principles at the concept stage of product development. Early-stage analysis allows teams to anticipate manufacturing constraints, select compatible materials, and structure designs around optimal manufacturing processes like injection molding or additive manufacturing.

This early focus minimizes costly rework and ensures alignment between product vision and manufacturing reality.

Use Standardized DFM Checklists

Standardized DFM checklists ensure that critical criteria aren’t overlooked. These may include:

- Proper draft angles for mold release

- Uniform wall thickness

- Avoidance of undercuts or deep cavities

- Accessibility for assembly tools

- Tolerance alignment with manufacturing capabilities

These checklists can be tailored by industry, material type, or manufacturing method, and should be reviewed by both the product design and manufacturing teams throughout the product development cycle.

Involve the Manufacturing Team Early

Successful DFM depends on early and frequent collaboration between engineering and manufacturing teams. By involving the manufacturing team from the outset, you can:

- Identify risks and limitations of chosen materials and geometries

- Align design elements with available tools and equipment

- Select manufacturing methods that match scale, precision, and timeline requirements

This alignment ensures that what’s being designed is not only possible to produce, but optimal to produce.

Leverage Simulation and Prototyping Tools

Modern simulation tools allow teams to visualize how parts will behave during manufacturing and assembly. Finite element analysis (FEA), mold flow simulation, and 3D prototyping help validate decisions before physical production begins.

Kenvox, for example, integrates several of these tools as part of its design review process to anticipate material flow issues in injection molding or to refine parts for additive manufacturing constraints. The result is fewer surprises, reduced material waste, and a smoother path to production.

Build Feedback Loops Across the Lifecycle

DFM is not a one-time event. Establish ongoing feedback loops between product development, manufacturing, and quality assurance teams. Post-production evaluations help identify any residual assembly errors, bottlenecks, or material inefficiencies that can be addressed in future designs.

These insights inform a culture of continuous improvement, where every project benefits from the learnings of the last.

Why DFM is a Strategic Investment, Not Just a Design Philosophy

While it’s easy to frame Design for Manufacturability as a technical best practice, its true value lies in how it shapes the business outcomes of product development.

Accelerates Time to Market

DFM reduces delays caused by redesigns, tooling adjustments, or post-prototype issues. When the manufacturing team and design engineers are aligned, products move from concept to production with greater speed and fewer friction points, shortening the product development cycle and accelerating revenue.

Improves Product Quality and Reliability

Products designed with manufacturing in mind are less prone to defects, inconsistencies, or assembly errors. Whether you’re working with precision components, injection molded parts, or complex assemblies, DFM helps ensure that what’s designed is also highly manufacturable, resulting in consistent product quality at scale.

Drives Long-Term Cost Efficiency

The initial investment in DFM pays dividends throughout the product’s lifecycle:

- Fewer prototypes and redesigns

- Lower tooling costs

- Reduced material waste

- Faster, more efficient assembly processes

Over time, these cumulative cost savings can easily add up to tens or hundreds of thousands of dollars, especially for products entering mass production.

Enhances Cross-Functional Resilience

DFM promotes cross-functional thinking; connecting design, engineering, and manufacturing methods into a unified system. This reduces siloed decision-making and builds organizational agility to respond to supply chain changes, material constraints, or market shifts.

In volatile markets where efficiency is everything, companies that integrate DFM gain resilience that goes beyond technical execution.

Don’t Let Design Decisions Drain Your Budget

Every successful product begins with a design, but only those built with design for manufacturability (DFM) succeed at scale. When the design process overlooks core manufacturing principles, companies risk costly delays, wasted raw materials, high labor costs, tooling issues, and compromised product quality. These problems often emerge in the manufacturing stage, leading to inefficient manufacturing operations, missed deadlines, and increased production costs.

By implementing DFM principles early in the design phase, design and manufacturing teams can identify potential manufacturing challenges, optimize assembly processes, and minimize material waste. This integration reduces tooling costs, lowers labor costs, and helps to minimize production costs while improving quality control and ensuring compliance with strict quality standards and regulatory compliance requirements.

At Kenvox, we’ve built the DFM process into the DNA of how we operate. From early CAD analysis to material selection, from printed circuit board layouts and surface mount technology to final assembly line validation, our engineering team applies proven strategies to reduce manufacturing costs, enhance production efficiency, and achieve significant cost savings. We help ensure your product can be manufactured efficiently under normal operating conditions, at any production volume, whether in mass production for the electronics industry, aerospace industry, or broader manufacturing industry.

Our focus is on efficient production using standard components and standardized components wherever possible, applying modular design to reduce complexity in the production line. These approaches deliver cost reduction, lower material costs, and result in reduced material waste. The outcome is a streamlined iterative process that strengthens overall efficiency, enhances product performance, and drives greater customer satisfaction.

By addressing key manufacturing considerations during the design stage, Kenvox enables companies to reduce costs, save money, and accelerate time to market. We work closely with design engineers and manufacturing engineers to balance manufacturing requirements with innovation, ensuring access to needed manufacturing equipment, managing material availability, and helping you achieve optimal results in your production processes.

Ready to future-proof your product development?

Contact us to talk about how Kenvox can support you in implementing DFM, aligning your design and manufacturing processes, and giving you a true competitive advantage by building better products from the very beginning.