high-speed cnc,edm

slow wire-cutting

high-speed cnc,edm

slow wire-cutting

Leading professionals in the tool/mold manufacturing industry.

Kenvox maintains strict quality control, deadlines, and voice activities with internal staff.

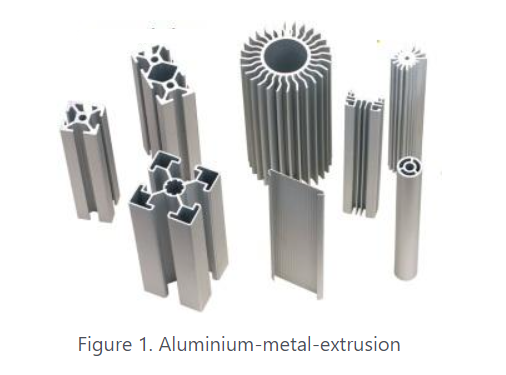

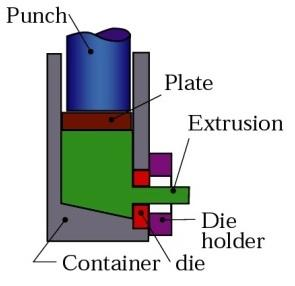

Metal Extrusion is a metal-forming manufacturing process in which a cylindrical billet inside a closed cavity is forced to flow through a die of the desired cross-section. These fixed cross-sectional profile extruded parts are called “Extrudates” and are pushed out using either a mechanical or hydraulic press. The process, patented by Joseph Bramah, was first used to extrude lead pipes by Thomas Burr

The most commonly extruded materials are Aluminium, Copper, Steel, Magnesium, and Lead. Plastics and ceramics are also extruded extensively but not discussed in this article.

Metal extrusion can be subdivided and grouped into the following categories depending on the direction of extrusion flow, the medium used to apply force, working temperature, etc.

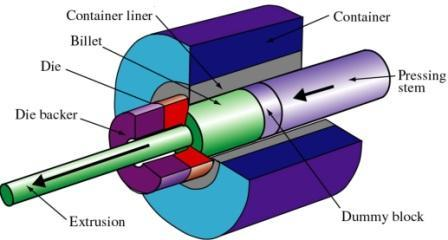

Direct Extrusion, sometimes called Forward Extrusion, is the most common type of extrusion. As shown in the figure below, the process begins by loading a heated billet (only for hot extrusion, discussed later) into a press cavity container where a dummy block is placed behind it. Then the mechanical or hydraulic ram presses on the material to push it out through the die. Then, while still hot, the part is stretched to straighten. This process is beautifully animated by Core Materials.

Figure 2 – Direct extrusion (source: Kalpakjian & Schmid)

Under direct extrusion, the high friction caused by steels at higher temperatures is reduced using molten glass as a lubricant while oils with graphite powder are used for lubrication for low temperatures. The dummy block protects the tip of the pressing stem (punch or ram) in hot extrusion. When the punch reaches the end of its stroke, a small portion of the billet called the “butt end” cannot be pushed through the die opening.

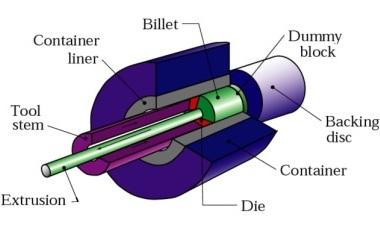

In Indirect Extrusion, the die is located at the end of the hydraulic ram and moves towards the billet inside the cavity to push the material through the die. This is illustrated in figure 2 below.

Figure 3 – In-direct extrusion (source: Kalpakjian & Schmid)

This process consumes less power due to the static billet container causing less friction on the billet. However, supporting the extruded part is difficult when the extrudate exits the die.

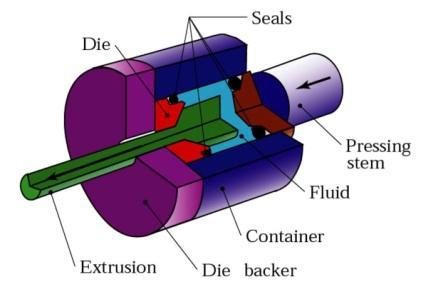

In hydrostatic extrusion, the chamber/ cavity is smaller than the billet and filled with hydraulic fluid, which transfers the force from the ram to the billet, as shown in figure 3. Although tri-axial forces are applied by the fluid, the pressure improves billet formability on the billet. Sealing the fluid must be considered early to avoid any leaking and reduce pressure issues.

Figure 4 Hydrostatic extrusion process (Kalpakjian & Schmid)

Although the hydraulic fluid eliminates the friction between the wall and the billet by isolating them, due to the specialised equipment requirement, the high set-up time and low production rate limit its usage in the industry compared to other extrusion processes.

In Lateral Extrusion, the container is in a vertical position, as shown in the image, and the die is on the side. This process is suitable for low melting point material.

Figure 5 – lateral extrusion process schematic (source : Kalpakjian & Schmid)

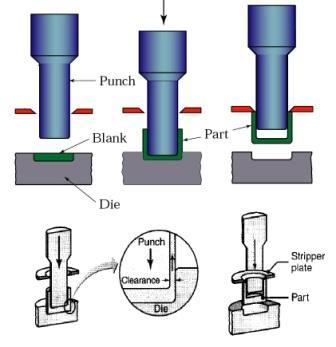

Impact extrusion is part of the cold extrusion category, very similar to In-direct extrusion and limited to softer metals such as Lead, Aluminium and copper. As the schematic illustrates, the punch is pushed down at high speed and has extreme force on the slug to extrude backwards. The thickness of the Extrude is a function of the clearance between the punch and the die cavity. The Extrudates are slid off the punch using a stripper plate.

Figure 6 Impact extrusion process (source: Kalpakjian & Schmid)

For impact extrusions, a mechanical press is often used, and the part is formed at high speed and over a relatively short stroke

Since the forces acting on the punch and die extremely high, tooling must have sufficient impact resistance, fatigue resistance and strength for extruding metal by the impact. Impact extrusion can be divided into the following three types by material flow.

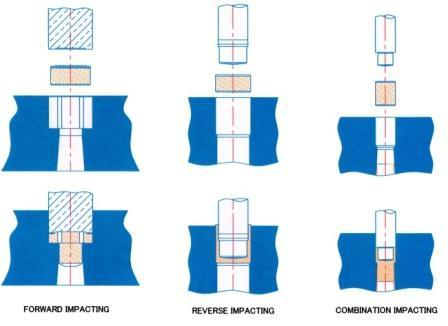

Figure 7 Types of Impact extrusion process (source : Kalpakjian & Schmid)

In forward impact extrusion, the metal flows in the same direction that the force is delivered, while it flows in the opposite direction in reverse impact extrusion. As the image shows above, the metal flows in both directions in combination.

Depending on the material condition and process variables, extrudates can develop many defects that could affect the quality of the end product. These defects can be grouped under the following three defects.