The plastics industry is undergoing a powerful transformation driven by the convergence of sustainability pressures, precision engineering, and digital manufacturing advancements.

Today, plastic manufacturing is no longer just about mass production; it’s about crafting intelligent, responsible, and resilient solutions for the future.

As the demand for biodegradable plastics, smart plastics, and high-performance plastics surges, innovations like multi-material plastic injection molding, plastics recycling technologies, and 3D printing are reshaping how products are designed, developed, and delivered. These shifts are not isolated; they’re part of a broader move toward the circular economy and supported by initiatives from platforms like the Plastics Industry Association.

Read on to learn more about the innovations and how with over three decades of experience in precision plastic fabrication and a firm commitment to sustainable, cutting-edge manufacturing, Kenvox is redefining what’s possible in plastic manufacturing innovations. From concept to completion, Kenvox integrates advanced materials, injection molding, and smart automation to deliver scalable, customized solutions across industries.

The Changing Landscape of Plastic Manufacturing

The modern plastics manufacturing industry is under mounting pressure to evolve. On one end, global manufacturers must meet growing market demand across sectors like the automotive industry and medical devices. On the other hand, they face intensifying scrutiny over environmental impact, particularly concerning single-use plastics and the effectiveness of current plastics recycling systems.

In response, innovation has become non-negotiable.

- New Plastics: Materials like bio-based plastics, recyclable plastics, and biodegradable plastics are gaining traction, not only for their lower environmental and carbon footprint but also for their adaptability in precision manufacturing.

- New Recycling: The rise of chemical recycling and the dissolution recycling process, pioneered by chemical engineers, is enabling better reclamation of plastic materials, closing the loop on waste, and supporting a true circular plastics network.

- Policies Pushing for Changes: Governments and organizations like the Plastics Industry Association continue to champion these efforts, pushing for integration of advanced plastics recycling methods that help reduce plastic waste and tighter standards for sustainable plastics development.

- Industry Demanding Innovation: Meanwhile, industries that rely on engineered components, from automotive applications or sterile medical devices, are seeking innovative and sustainable solutions that offer both performance and responsibility.

Kenvox’s expertise intersects perfectly with these trends. By embedding Industry 4.0 practices, leveraging collaborative robots, and integrating the latest digital solutions into the plastic manufacturing process, Kenvox is positioned to lead in both technological advancement and ecological stewardship.

Breakthroughs Defining Plastic Manufacturing Innovations

Plastic manufacturing is being redefined by a wave of technological breakthroughs that blend precision, sustainability, and digital intelligence. These innovations not only improve product performance and reduce plastic waste but also elevate design possibilities and production efficiency for industries that rely heavily on advanced plastic components.

Evolving Injection Molding Techniques

Modern injection molding has evolved far beyond traditional mass production. Today’s systems support micro injection molding for ultra-precise components, gas-assisted injection molding for custom plastics, complex geometries, and multi-material injection molding for seamless integration of different polymers in a single cycle. These capabilities enable manufacturers to create lightweight, durable, and intricate parts with minimal plastic waste, ideal for sectors like automotive and medical devices.

Additive Manufacturing and 3D Printing

3D printing is transforming how prototypes and custom plastic parts are developed. It enables rapid iteration, complex geometries, and on-demand production, particularly valuable in medical and electronics applications. When combined with injection molding, 3D printing supports hybrid workflows that accelerate development without compromising on form or function.

Artificial Intelligence and Smart Process Control

Artificial intelligence (AI) is being deployed across the plastic processing lifecycle to optimize mold design, monitor machine performance, and predict material behavior in real-time. By leveraging AI algorithms, manufacturers can reduce defects, improve energy efficiency, and ensure consistency in quality. Smart plastics—materials with built-in sensory or reactive capabilities—are also emerging as functional innovations in applications ranging from wearables to industrial components.

Sustainable Plastics and Recycling Innovations

The integration of recycled plastics and chemical recycling methods into mainstream manufacturing has shifted the narrative from waste management to circularity. Techniques like dissolution recycling and advanced plastics recycling enable the recovery of high-quality polymers that can be reused in critical applications. Innovations in bio-based plastics and bacteria breakdown research further expand the boundaries of what sustainable plastic products can achieve.

Kenvox integrates many of these breakthroughs across its operations, combining proven molding excellence with forward-leaning innovation. Their use of precision molding, in-house design for manufacturability (DFM), and investment in cleanroom and smart environments positions them at the leading edge of plastics innovation today.

Kenvox’s Contributions to Innovation

With over 190 injection molding machines ranging from 30 to 1,000 tons, Kenvox handles everything from high-precision prototypes to high-volume manufacturing with seamless agility. Their facilities are equipped to support:

- Micro injection molding for ultra-precise components

- Dual-color molding for visually and functionally complex parts

- Cleanroom production for sterile or medical-grade applications

Advanced DFM for High-Performance Plastics and Speed

A major pillar of Kenvox’s innovation is their advanced Design for Manufacturability (DFM) methodology. From the very first design review, engineers work hand-in-hand with clients to optimize each plastic part for:

- Structural integrity and function

- Moldability and cycle time efficiency

- Material performance and cost control

This proactive collaboration reduces iteration cycles, improves time-to-market, and ensures that the final product is ready for demanding real-world applications, whether in automotive interiors or biocompatible medical devices.

Highly Precise and Sophisticated Experts

Kenvox also excels in complex geometry and multi-material component production, allowing seamless integration of features and minimizing the need for secondary assembly. Their advanced tooling capabilities are a standout, with in-house management of:

- CAD/CAM design and simulation

- CNC high-precision machining

- Mold testing and validation under real production conditions

By keeping tooling in-house, Kenvox ensures faster turnaround times, tighter quality control, and full traceability throughout the development process.

Ultimately, Kenvox’s innovation strategy is built on vertical integration, precision control, and an unwavering commitment to helping clients realize their most challenging plastic manufacturing goals with speed, confidence, and excellence.

Smart Manufacturing at Kenvox

Kenvox’s leadership in plastic manufacturing innovations is reinforced by its adoption of smart manufacturing technologies, where automation, digital integration, and intelligent systems converge to elevate quality, speed, and efficiency.

Real-Time Visibility with ERP Integration

At the core of Kenvox’s operations is a proprietary Enterprise Resource Planning (ERP) system that unifies all production stages. From mold development and raw material management to QA checks and final delivery, this system enables:

- Real-time monitoring and analytics across the supply chain

- Immediate adjustments to production schedules and material flows

- Full traceability and accountability for every part and batch

Clients benefit from streamlined communication, faster lead times, and complete visibility throughout the manufacturing process.

Automation and Industry 4.0 Systems

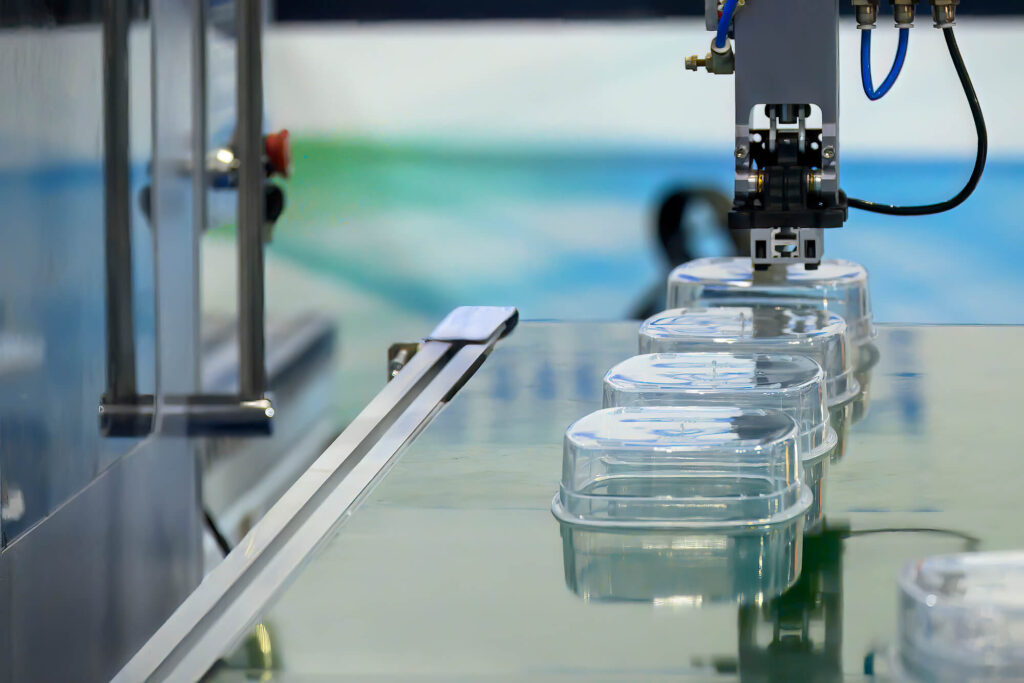

Kenvox integrates collaborative robots and intelligent automation to accelerate production and maintain precision. These systems:

- Handle insert loading, part extraction, and secondary processes with speed and consistency

- Minimize manual intervention to reduce human error and downtime

- Enhance productivity while maintaining tight quality control standards

Through the lens of Industry 4.0, Kenvox aligns manufacturing with digital intelligence, optimizing every phase of the operation.

Scalable for Any Project Scope

From prototyping to mass production, Kenvox’s smart infrastructure adapts to the unique demands of each project. Whether manufacturing sterile plastic parts for medical devices or durable automotive housings, the system supports:

- Flexible production volumes and shift responsiveness

- Custom material handling for recycled or advanced polymers

- Continuous feedback for process improvement and sustainability metrics

Kenvox delivers not only plastic parts but also smarter, faster, and cleaner production outcomes.

Sustainability Through Plastic Innovation

In today’s plastics industry, innovation is both about performance and responsibility. Kenvox is committed to advancing plastic manufacturing in ways that reduce plastic waste, conserve resources, and align with global efforts toward a more sustainable future and circular economy.

Integrating Recycled and Bio-Based Plastics

Kenvox can incorporate recycled plastics into its manufacturing workflows, helping reduce dependence on virgin materials. Through precise material sourcing and formulation, these recycled inputs meet stringent mechanical and aesthetic requirements, particularly for applications in consumer goods, automotive interiors, and custom enclosures.

In addition to post-consumer resins, Kenvox has explored the use of bio-based plastics and biodegradable plastics, working with select suppliers and material scientists to develop viable options for clients seeking low-impact alternatives. This includes experimenting with different recycling technologies, compostable polymers, starch-based blends, and bio-resins that break down more cleanly over time, without sacrificing durability.

Lean Manufacturing and Material Reduction

Sustainability also starts with efficiency. Kenvox’s engineering teams apply Design for Cost Reduction (DfCR) principles to reduce costs at the design phase. By rethinking wall thickness, part consolidation, and mold design, they minimize excess material while maintaining structural integrity and product function.

These initiatives are supported by energy-optimized machines and waste-reduction systems throughout production.

Certified Ethical and Responsible Operations

Kenvox’s sustainability commitment extends beyond materials. As a certified participant in the Business Social Compliance Initiative (BSCI), Kenvox adheres to internationally recognized standards in workplace safety, environmental stewardship, and ethical business conduct.

In addition, their operations are supported by key quality and sustainability certifications, including:

- ISO 9001 for quality management

- ISO 13485 for medical device manufacturing

- IATF 16949 for automotive sector quality assurance

These systems ensure that environmental performance is part of every step in the plastic manufacturing process: from development and tooling to final delivery.

Kenvox is helping in the transition toward sustainable plastics and long-term circularity within global supply chains.

Value-Added Capabilities That Set Kenvox Apart

Kenvox’s innovation in plastic manufacturing doesn’t end with molding. What truly sets the company apart is its full-spectrum suite of value-added services that enhance functionality, appearance, and market readiness of plastic components.

Advanced Surface Finishing and Customization

Kenvox offers a comprehensive range of in-house surface treatment options that give products a professional, branded, and often functional finish. These include:

- Pad printing for precise, multicolor branding and icons

- Laser engraving for permanent markings and traceability

- Vacuum plating for metallic finishes and enhanced durability

These manufacturing processes are performed under strict quality controls, ensuring consistency across high volumes and intricate parts, and allow Kenvox to reduce turnaround times, eliminate third-party handling, and maintain full control over surface quality and compliance.

Assembly, Packaging, and Logistics Integration

For clients seeking a turnkey solution, Kenvox provides custom assembly, labeling, and packaging directly on-site. This includes:

- Sub-assembly lines tailored to complex multi-part components.

- Automated labeling systems

- Customized packing protocols based on shipment type and destination.

This integration reduces handoffs and consolidates the production pipeline, and thus improving efficiency, inventory control, and cost-effectiveness. It also supports a cleaner handover between manufacturing and distribution, particularly for international clients with complex logistics networks.

Plastic Innovation Across Industries

Kenvox’s versatility in plastic manufacturing innovations is reflected in its ability to serve a wide spectrum of industries, each with distinct performance, compliance, and design requirements.

Automotive Industry

In the automotive industry, the demand for lightweight, durable, and precisely engineered plastic components is constant. Kenvox manufactures high-performance plastics for interior and exterior applications, supporting weight reduction, fuel efficiency, and design flexibility.

- Dual-color injection parts for dashboards and panels

- Functional components with integrated fasteners or inserts

- Materials designed for vibration resistance and thermal stability

Kenvox also complies with IATF 16949 standards, ensuring consistency, traceability, and quality across large-volume production runs.

Medical Devices

Medical plastics require absolute precision, cleanliness, and biocompatibility. Kenvox meets these demands with ISO 13485-certified cleanroom production for components like:

- Sterile housing for diagnostic equipment

- Custom-molded surgical tool handles

- Micro injection molded parts for portable medical devices

From raw material sourcing to packaging, every step is controlled to meet regulatory expectations and patient safety standards.

Consumer Electronics

The consumer electronics sector thrives on visual appeal, tight tolerances, and advanced form factors. Kenvox produces custom enclosures, casings, and functional plastic parts with surface treatments like laser engraving, vacuum plating, and pad printing.

Whether supporting thermal management, wireless signal flow, or ergonomic handling, Kenvox integrates design functionality with scalable aesthetics.

Household & Baby Products

Safety and usability are paramount in household goods and baby care items. Kenvox produces BPA-free, food-grade, and hypoallergenic plastic parts that adhere to strict international safety standards.

- Ergonomic baby bottle components

- Kitchen tools with overmolded grips

- Durable parts for appliances and cleaning devices

Kenvox ensures these everyday products are not only functional and safe but also appealing and built to last.

Why Partner with Kenvox for Plastic Manufacturing Innovations

More than a plastic parts supplier, Kenvox can be a strategic manufacturing partner that will help businesses transform concepts into world-class products. From early design collaboration to global delivery, Kenvox delivers unmatched value across the full plastic manufacturing lifecycle.

Vertically Integrated Manufacturing Powerhouse

Kenvox’s vertically integrated structure allows for complete in-house control over every stage of production. This includes:

- In-house mold design and fabrication

- Advanced injection molding (standard, dual-color, micro, gas-assisted)

- Cleanroom production and surface finishing

- Integrated assembly, labeling, and packaging

This model eliminates fragmentation, enhances coordination, and ensures faster response times when scaling plastic production or pivoting mid-project.

Proven Innovation Track Record

Kenvox has a longstanding track record of innovation across high-performance, sustainable, and smart plastic manufacturing. By blending traditional craftsmanship with modern technology—such as digitally-driven process control, 3D printing for prototyping, and recyclable material integration—Kenvox consistently delivers forward-thinking solutions for evolving market demands.

Global Reach with Local Execution

With large-scale production facilities in China and Vietnam, and business units in North America, Kenvox offers clients regional flexibility with global capacity. Whether you’re launching in Asia, scaling in Europe, or prototyping for North America, Kenvox delivers quality, speed, and logistical fluency that fits seamlessly into your supply chain.

Certified Reliability and Ethical Manufacturing

With certifications including ISO 9001, ISO 13485, IATF 16949, and BSCI, Kenvox meets the highest standards for quality, safety, and ethical production.

When businesses partner with Kenvox, they gain a vendor and a trusted, long-term ally in innovation, execution, and growth.

Let Kenvox Help You Take Advantage of the Top Plastic Manufacturing Innovations

The future of plastic manufacturing is being shaped by innovation, where sustainability, precision, and smart technologies are not optional, but essential. From high-performance automotive components to sterile medical devices and ergonomic consumer products, plastic is evolving into a smarter, cleaner, and more functional material. But innovation doesn’t happen in isolation and it requires a partner that can bridge concept with execution, vision with volume, and sustainability with scalability.

Kenvox is that partner.

Whether you’re optimizing an existing product or bringing a bold new concept to life, Kenvox delivers the infrastructure, expertise, and responsiveness needed to compete in today’s fast-moving global markets.Ready to elevate your plastic product with true manufacturing innovation?

Collaborate with Kenvox and turn ideas into industry benchmarks.