Have you ever wondered how some companies are able to bring their products to market at lightning speed while others seem to lag behind?

In the fast-paced world of product development, time is often just as critical as innovation itself. With increasing consumer demands and a competitive marketplace, businesses can’t afford to waste precious weeks or months on traditional manufacturing processes. Rapid injection molding has emerged as a game-changing solution, allowing teams to streamline their workflows, reduce lead times, and accelerate their overall time-to-market.

From enhanced design flexibility to reduced costs, this approach not only speeds up production but also empowers teams to test, iterate, and refine their products more effectively. If you’re eager to learn how speed can impact your product’s journey from concept to reality, read on as we explore the advantages of rapid injection molding and what you need to know to leverage its full potential.

How Rapid Injection Molding Differs from Traditional Plastic Injection Molding

What most need to know about rapid injection molding is that it’s a faster, more cost-effective alternative to traditional plastic injection molding, designed primarily for prototyping, small batch runs, and low-volume production. The key differences between rapid and traditional plastic injection molding are:

- Production Tooling: Traditional plastic injection molding uses hardened steel molds that are built for high-volume, long-term production. These molds are expensive and take weeks or months to create. In contrast, rapid injection molding uses mold materials like aluminum or soft steel molds.

- Mold cost: These rapid molds have shorter setup times, are quicker to produce (often in days or weeks), and cost significantly less, making them ideal for smaller mold production volumes or bridge tooling between prototyping and full-scale production.

- Materials Used: While both methods use similar thermoplastic materials, rapid molding is often more flexible in terms of materials because aluminum molds handle different types of plastic resins well. However, these rapid molds have a lower tolerance for high heat and pressure levels compared to hardened steel, meaning that they may not be ideal for certain high-performance plastic materials in large-scale production, although recent innovations are changing that for many applications.

- Cycle Time and Costs: Rapid injection molding offers faster cycle times due to quicker mold creation and shorter production runs. While it may not be as efficient for mass production, it provides excellent speed and flexibility for initial product launches, prototypes, or testing before full production tooling is developed.

The Materials used for Rapid Injection Molds

In rapid molding, the material choice for constructing molds is critical to both the mold’s functionality and lifecycle.

Aluminum Molds

Utilizing aluminum rapid injection molds offers several distinct advantages that streamline the manufacturing process.

First, aluminum molds considerably reduce production lead times due to their excellent thermal conductivity, which speeds up the cooling process of molded parts. This efficiency is vital when prototyping new products, allowing for rapid iterations and quicker market entry.

Additionally, aluminum is less dense than other metals used in mold making, which not only facilitates faster machining but also reduces wear on injection molding machines, enhancing their longevity and reducing maintenance costs.

These attributes make aluminum molds a preferred choice in manufacturing environments where quick turnaround times and cost efficiency are vital, ensuring a smoother and more predictable production cycle.

Soft and Semi-Hardened Steels

Shifting the focus to soft and semi-hardened steels, these materials are also frequently utilized in the creation of rapid injection molds.

Preferred for their versatility, soft and semi-hardened steels provide a balanced compromise between durability and cost-effectiveness.

These steel grades are particularly advantageous for testing prototypes and small batch production of components, where modifications might be necessary based on the testing outcomes.

Their capacity to withstand repeated mold cycles while maintaining dimensional stability is essential for iterative testing phases in product development.

Using these materials allows developers to refine component designs swiftly and efficiently, ensuring that the final product meets the stringent requirements of performance and reliability, thereby streamlining the path from concept to market readiness.

Key Benefit of Rapid Injection Molding for Product Development

From quick time to markets to lower cost and rapid prototyping, rapid injection molding offers large numbers of benefits to product developers compared to conventional injection molding or even other methods.

Faster Time-to-Market

Accelerating the journey from concept to market, rapid injection molding stands out as a pivotal advantage for businesses aiming to enhance their competitiveness in fast-paced industries.

This technique notably shortens the development cycle, enabling a faster time-to-market for new products.

Particularly in sectors like aerospace, where product lifecycle and innovation speed are critical, the ability to swiftly shift from design to production can determine market leadership.

Rapid injection molding not only expedites this process but also allows manufacturers to respond quickly to evolving market demands and technological advancements.

Competitive Pricing for Rapid Prototyping

Traditional injection molding requires costly, hardened steel molds, making it expensive for small-scale production runs or prototyping. In contrast, rapid injection molding with Aluminum or soft steel molds offers a much more affordable alternative.

Rapid molding offers competitive pricing for rapid prototyping, which is essential for cost-effective product development.

This process not only meets stringent budget requirements but also adheres to specific material properties needed for functional testing and design validation.

By streamlining the prototyping phase, companies can allocate resources more efficiently, ensuring that product development is both agile and economical.

Moreover, the ability to rapidly iterate detailed designs based on real-time feedback and performance data allows for cost adjustments before full-scale production, optimizing the overall expenditure.

The competitive pricing of this rapid molding process empowers businesses to maintain control over both timelines and financial outlays, enhancing their ability to respond to market demands swiftly and effectively.

Short-Run Production Process

The short-run production process emerges as another significant advantage for product development.

This method utilizes durable aluminum molds that can efficiently produce limited quantities of parts, offering a cost-effective solution for small-scale production.

Furthermore, the adaptability of surface finish options allows developers to achieve the desired aesthetics and functionality, providing enhanced control over the final product. This flexibility is particularly valuable in markets where demand can fluctuate, making the short-run production process an essential tool for agile product development strategies.

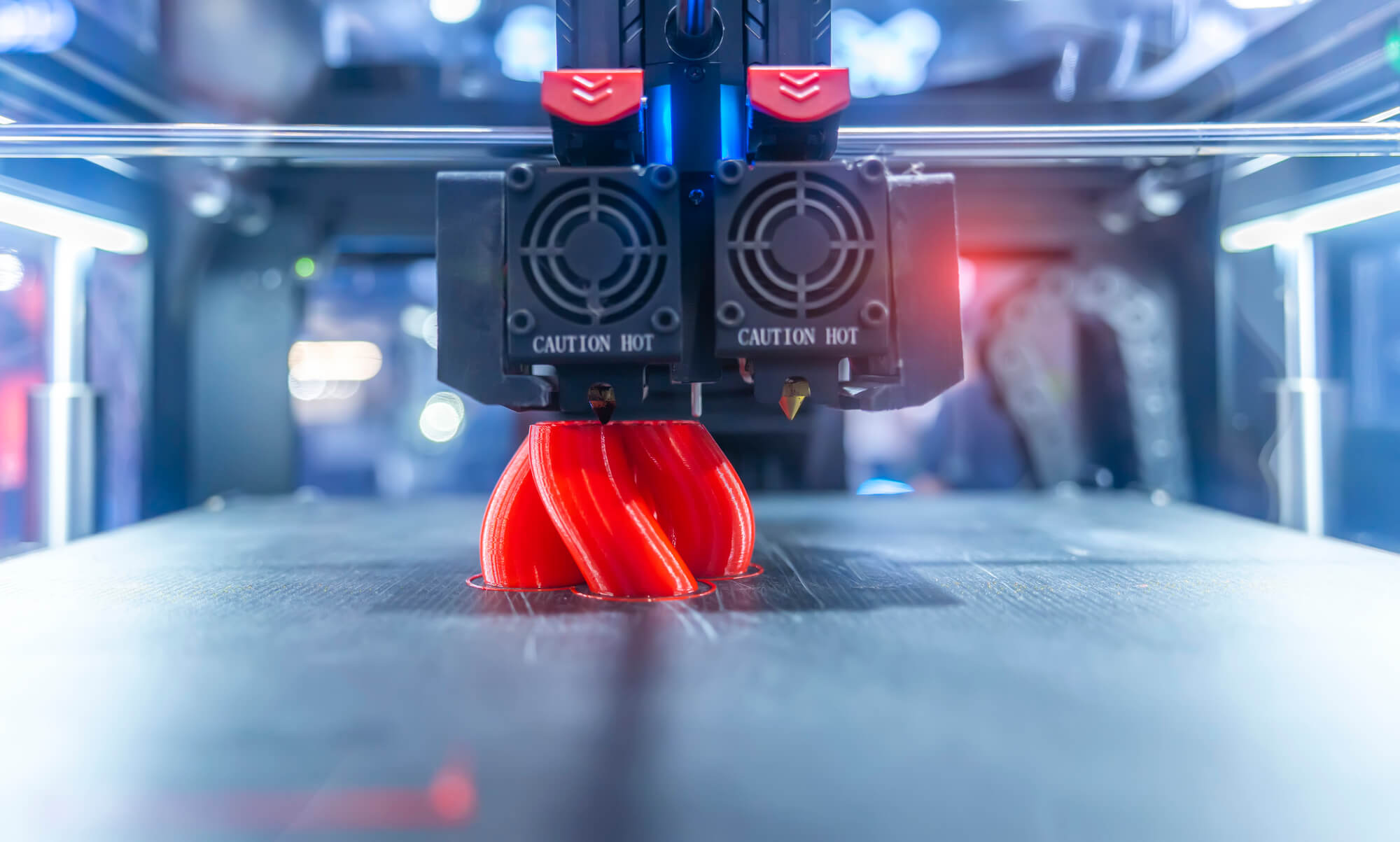

Realistic Prototypes with Accurate Material Properties

One of the key benefits of rapid injection molding over other prototyping methods, such as 3D printing, is that it allows for the creation of parts with the actual material properties of the final products.

These prototypes can be made using the same resin or plastic materials that will be used in full-scale production, ensuring that the parts have the necessary strength, heat resistance, and other performance characteristics.

Additionally, the surface finish of the parts created with rapid injection molding is much closer to the final production quality, allowing for more accurate testing of both aesthetics and functionality.

Flexibility in Design Iterations

Rapid injection molding offers unparalleled flexibility in design iterations, making it an invaluable tool for product development. This technique allows for quick adjustments to be made through precise machining, enabling designers to experiment with different inserts and optimize their products efficiently.

Such flexibility is essential across various industries where market demands and technological advancements are continuously evolving. By facilitating easy modifications, developers can iterate designs or fix potential issues with their original designs without the costly and time-consuming need to create new molds for each variation.

This not only speeds up the development process but also empowers teams to achieve higher quality and performance in their final products. Rapid molding, therefore, stands out as a critical strategy for maintaining a competitive advantage in a fast-paced market.

Bridge Tooling for Low-Volume Production

Rapid injection molding is also an excellent solution for bridge tooling, which helps companies transition from prototyping to full-scale production.

This production method utilizes temporary aluminum or soft steel molds that can produce high-quality parts without the cost or time commitment required for full-scale production tools. These molds, equipped with fewer mold cavities, are ideal for generating several hundred to thousands of units.

This allows manufacturers to continue testing the product or even start shipping small orders while the final tools are in development, maintaining momentum in their production process.

Bridge tooling allows manufacturers to evaluate product functionality, gather market feedback, and verify design specifications in a real-world context.

Industries that Benefit the Most from Rapid Injection Molding

Rapid injection molding has emerged as a pivotal technology in several key industries where short cycle times, rigorous quality standards, and precision are paramount.

Automotive

The automotive industry stands as one of the primary beneficiaries of rapid injection molding, leveraging this advanced manufacturing process to enhance both design flexibility and speed to market.

This technique allows manufacturers to quickly produce high-quality parts with complex shapes and robust surface finishes, essential for the visually appealing and functional components of modern vehicles.

The ability to rapidly prototype automotive parts not only accelerates development cycles but also empowers designers and engineers to experiment with different materials and surface textures without costly delays.

Consequently, the automotive sector can swiftly adapt to market changes and consumer preferences by implementing design modifications and innovations that meet stringent industry standards, ultimately leading to a more dynamic production environment and enhanced product offerings.

Consumer Electronics

Several industries reap the advantages of rapid injection molding, with consumer electronics emerging as a notable beneficiary.

In this sector, where product life cycles are short, and demand for innovation is high, rapid injection molding facilitates swift market entry. This technique allows for quick prototyping and iterative testing, enabling manufacturers to refine designs with precision before mass production commences.

Such agility guarantees that consumer electronics companies can rapidly respond to evolving consumer preferences and technological advancements, maintaining competitiveness and market relevance.

Additionally, the ability to swiftly produce high-quality, complex components like casings, connectors, and buttons at reduced costs empowers firms to efficiently manage resources and control production schedules, optimizing overall operational efficiency.

Aerospace

Aerospace companies greatly benefit from rapid injection-molded parts, as the industry demands high-performance components with complex geometries and tight tolerances.

This technology notably enhances product development by enabling quicker iterations and precise component fabrication.

Key advantages include:

- Reduced Time to Market: Rapid injection molding accelerates the design verification process, allowing aerospace engineers to test and modify designs swiftly, thereby shortening the development cycle.

- Cost Efficiency: Minimizing the use of traditional manufacturing methods reduces upfront costs associated with mold-making and setup, which is particularly beneficial for low-volume production typical in aerospace applications.

- Material Versatility: This method supports a wide range of high-performance materials essential for aerospace components, facilitating innovation and adherence to stringent industry standards.

Medical Devices

The medical industry often requires small production runs for testing or regulatory approval. Rapid injection molding allows medical device companies to create precise parts such as plastic enclosures, diagnostic tools, and small components for surgical instruments without needing to go into high-volume production.

What the Future Holds for Rapid Injection Molding

The future of rapid injection molding holds exciting potential as technology continues to evolve, expanding its capabilities beyond prototyping and low-volume production. Advancements in materials, production tooling, and automation are pushing the boundaries of what rapid injection molding can achieve, making it increasingly competitive for higher-volume production and more complex parts.

Handling High-Volume Production

One key area of future development is the ability of rapid injection molding to scale for high-volume production. Improvements in the durability of aluminum molds and enhanced machining techniques are making it possible to extend rapid injection mold lifespans and produce larger quantities of parts without compromising speed or quality. With the integration of more advanced materials and insert tooling, manufacturers will be able to bridge the gap between rapid and traditional injection molding, making it feasible to use rapid molding for extended runs.

Improvements in Quality and Precision

Technological advancements are also driving quality improvements in rapid injection molding. New developments in mold machining, enhanced surface finish capabilities, and better heat management techniques are allowing for more precise components that meet even the most stringent tolerances. As automation becomes more widespread, manufacturers can also achieve tighter quality control and consistency across production cycles, further reducing the need for manual intervention and post-production finishing.

Integration with Digital Manufacturing

The future of rapid injection molding will likely see greater integration with digital manufacturing technologies, such as AI-driven design, predictive analytics, and real-time monitoring systems. These innovations will streamline the entire prototyping and production process, enabling faster cycle times, reducing errors, and optimizing materials usage. Combined with Industry 4.0 trends, rapid injection molding will be more agile, data-driven, and connected, further enhancing product development processes.

Overall, as rapid injection molding evolves, it will continue to offer manufacturers a more versatile, high-quality, and efficient solution for product development, bringing them closer to full-scale production at an accelerated pace.

Conclusion

In summary, rapid injection molding represents a transformative approach in manufacturing, offering substantial reductions in development lead times and fostering greater flexibility in design iterations.

By enabling the production of high-quality prototypes that closely emulate final products, this technique enhances the competitive edge of industries such as automotive, consumer electronics, and aerospace.

However, it is imperative to address the inherent challenges and considerations to fully leverage the potential benefits of rapid injection molding in product development.mo